OPTO-MATIC注油器相对于轴/轴承/挡油环旋转的放置灵活性和条件(中英文)

Opto-Matic注油器相对于轴/轴承/挡油环旋转的放置灵活性和条件

The Flexibility and Conditions for Opto-Matic Oiler Placement Relative to Shaft/Bearing/Flinger Rotation

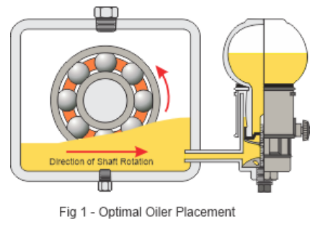

传统上,Opto-Matic 注油器相对于轴、轴承和挡油环旋转方向的放置位置被认为是实现最佳性能的关键(图 1)。然而,实际经验和操作条件表明,只要考虑到某些因素,即使安装在另一侧,油器也能有效运行。本文探讨了这种灵活性,同时承认需要对特定操作条件进行态势感知。

简介

虽然通常建议将 Opto-Matic 油器安装在与旋转方向一致的位置以获得理想的性能,但应该强调的是,这并不是有效功能的绝对要求。在各种条件下,只要考虑到特定的操作因素,即使安装在另一侧,油器也能可靠地运行。

The placement of the Opto-Matic Oiler in relation to the direction of shaft, bearing, and flinger rotation is traditionally considered crucial for optimal performance (Fig.1). However, practical experience and operational conditions have shown that the oiler can function efficiently even when mounted on the opposite side, given certain considerations. This blog post explores this flexibility while acknowledging the need for situational awareness regarding specific operational conditions.

Introduction

While it is generally advised to mount the Opto-Matic Oiler in alignment with the direction of rotation for ideal performance, it should be highlighted that this is not an absolute requirement for effective functionality. Under various conditions, the oiler has been observed to perform reliably even when mounted on the opposite side, providing that specific operational factors are considered.

旋转方向和注油器位置:平衡视角

The Direction of Rotation and Oiler Placement: A Balanced Perspective

理想位置与替代位置

尽管 Trico 的官方指南建议将注油器安装在与旋转方向相对应的轴承箱一侧,但经验表明,在特定条件下,安装在相反侧也可以成功运行。

运行条件:启动和连续运行

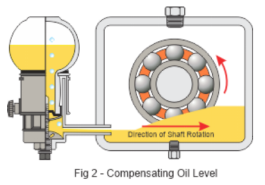

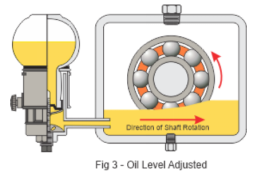

当注油器放置在与旋转方向相反的一侧时,它会补偿油膨胀(图 2 - 注油器进料,注油器储液器中可见气泡),从而仍然充分保持油位(图 3)。这种安装位置的灵活性允许更广泛的安装选项,只要人们了解机器运行的具体条件即可。

设备关闭

即使关闭后,由于旋转方向导致的任何油位升高都会在下次启动时自动补偿,只要人们了解这种行为并进行必要的操作调整即可。

Ideal vs. Alternative Placement

Though Trico's official guidelines recommend that the oiler be installed on the side of the bearing housing that corresponds with the rotation direction, experience shows that mounting on the opposite side can also result in successful operation, subject to certain conditions.

Operational Conditions: Startup and Continuous Operation

When the oiler is placed on the side opposite the direction of rotation, it compensates for the oil swell, (Fig. 2 - oiler feeding, air bubbles visible in oiler reservoir) thus still adequately maintaining the oil level (Fig. 3). This flexibility in mounting position allows for a broader range of installation options, provided one is aware of the specific conditions in which the machinery operates.

Equipment Shutdown

Even after shutdown, any elevated oil levels due to the direction of rotation are automatically compensated for at the next startup, provided one is aware of this behavior and makes necessary operational adjustments.

应对极端条件

Navigating Extreme Conditions

非理想放置的注意事项

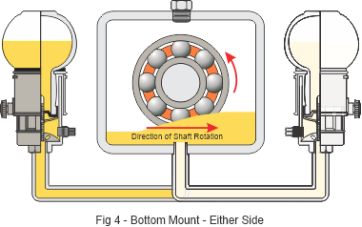

当处理较小轴承座中的较大轴承、多个挡油环或较小注油器储油器时,放置不当可能会带来挑战。但是,即使在这些极端情况下,也可以通过从轴承座底部安装注油器来保持有效运行。

特殊情况:挡油环流量问题

在安装挡油环的情况下,在另一侧安装仍然是可行的。挡油环引起的电流通常起到泵送作用,可以通过战略性放置(底部安装)和操作调整来减轻。

建议和结论

传统的指导主张将 Opto-Matic 注油器与轴旋转方向对齐,这是最佳实践建议,但并非不可动摇的规则。当注油器安装在另一侧时,仍然可以实现有效运行,前提是人们始终对特定的操作条件和注意事项保持警惕。

这种更广泛的理解为工业操作员和维护人员提供了更大的灵活性,特别是在复杂或受限的环境中。

Considerations for Non-Ideal Placement

When dealing with larger bearings in smaller housings, multiple flingers, or smaller oiler reservoirs, improper placement may pose challenges. However, even in these extreme cases, effective operation can be maintained by mounting the oiler from the bottom of the bearing housing.

Special Cases: Flinger Flow Issues

In scenarios where flingers are installed, mounting on the opposite side can still be viable. The flinger-induced current, which typically acts as a pumping action, can be mitigated through strategic placement (bottom installation) and operational adjustments.

Recommendations and Conclusions

The traditional guidance advocating for alignment of the Opto-Matic Oiler with the direction of shaft rotation serves as a best-practice recommendation but is not an unyielding rule. Effective operation is still attainable when the oiler is mounted on the opposite side, given that one remains vigilant about specific operational conditions and considerations.

This broader understanding provides greater flexibility for industrial operators and maintenance personnel, particularly in complex or constrained environments.

声明:

- 文章转载自TRICO,由爱泽工业翻译,如有侵权,请联系删除!

- 如有偏颇,欢迎指正!

上一篇:基础篇——平衡阀介绍(中英文)

沪公网安备31011002006738号

沪公网安备31011002006738号