无线振动传感器:综合指南(中英文)

什么是无线振动传感器?

What is a Wireless Vibration Sensor?

无线振动传感器测量和分析机械和工业设备振动。这些传感器在预测性维护中发挥着至关重要的作用,确保各行各业的机械持续高效运行。

A wireless vibration sensor measures and analyzes machinery and industrial equipment vibrations. These sensors play a crucial role in predictive maintenance, ensuring machinery’s continuous and efficient operation in various industries.

无线振动传感器的主要特点

Key Features of a Wireless Vibration Sensor

• 优质的加速度计技术:无线振动传感器利用优质的加速度计技术来精确检测和捕获振动数据。

• 无线连接:它们配备无线通信功能,可将数据无缝传输到中央监控系统。

• 实时监控:这些传感器可实时洞察设备振动情况,从而可以立即分析机器的健康和性能。

• 主动维护:通过持续监控振动模式,无线传感器支持主动维护方法,从而可以尽早发现潜在问题,防止代价高昂的停机。

• 远程可访问性:用户可以远程访问振动数据,通过互联网连接从任何地方进行监控和分析。

• 应用范围广泛:无线振动传感器可应用于制造业、能源、汽车等各个行业,有助于提高运营效率并降低维护成本。

• Advanced Accelerometer Technology: Wireless vibration sensors utilize state-of-the-art accelerometer technology to detect and capture vibration data precisely.

• Wireless Connectivity: They are equipped with wireless communication capabilities, enabling seamless data transmission to a central monitoring system.

• Real-time Monitoring: These sensors provide real-time insights into equipment vibrations, allowing for immediate analysis of machine health and performance.

• Proactive Maintenance: Through ongoing monitoring of vibration patterns, wireless sensors empower proactive maintenance approaches, enabling the early detection of potential problems to prevent costly downtimes.

• Remote Accessibility: Users can remotely access vibration data, facilitating monitoring and analysis from anywhere with an internet connection.

• Wide Range of Applications: Wireless vibration sensors find applications in diverse industries, including manufacturing, energy, automotive, and more, contributing to enhanced operational efficiency and reduced maintenance costs.

无线振动传感器基础知识

Wireless Vibration Sensor Basics

无线振动传感器测量振动变化并及早检测旋转机器故障以避免故障。许多维护主管将振动传感器用作其整体状态监测程序的一部分。这是因为大约 90% 的机器故障属于以下四个主要类别之一:

• 错位

• 不平衡

• 松动

• 轴承损坏

合适的无线振动传感器可以捕捉到这些常见的机器故障。

无线振动传感器使用 WiFi、LTE 或以太网等网络连接将测量值连续传输到软件。例如,无线传感器可以将数据发送到计算机化维护管理系统 (CMMS) 软件,在那里可以存储和分析数据。

A wireless vibration sensor measures vibration changes and detects rotating machine failures early to avoid breakdowns. Many maintenance leaders use vibration sensors as part of their overall condition monitoring program. That’s because some 90 percent of machine faults fall into one of four main categories:

• Misalignment

• Imbalance

• Looseness

• Bearing damage

The right kind of wireless vibration sensors can catch those common machine faults.

A wireless vibration sensor uses a network connection like WiFi, LTE, or ethernet, to continuously transmit measurements to software. For instance, a wireless sensor may send data to computerized maintenance management system (CMMS) software where the data can be stored and analyzed.

无线振动传感器的优势:

Benefits of a Wireless Vibration Sensor:

• 与有线传感器相比,无线振动传感器更具成本效益且易于安装

• 几乎可以从任何地方访问远程状态监测数据

• 根据传感器和软件启用筛选或数据分析

• 收集和监测数据以尽早发现故障,避免资产故障

• Wireless vibration sensors are more cost-effective and easy to install compared to wired sensors

• The remote condition monitoring data is accessible from almost anywhere

• Enables screening or data analysis depending on the sensor and software

• Collects and monitors data to catch faults early to avoid asset failure

振动传感器的工作原理

How a Vibration Sensor Works

无线振动监测传感器从安装它的机器生成振动信号,对其进行转换和处理,然后将实时数据发送到 Web 应用程序。该资产管理软件可让维护团队查看和分析数据趋势,以及执行数据分析。

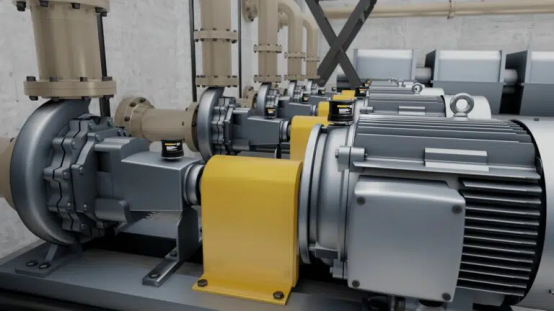

通过无线振动监测,传感器可以跟踪和记录振动水平测量值,用于确定旋转机械(如压缩机和泵(驱动电机、从动装置)以及皮带、齿轮、轴、轴承和构成机械系统的其他部件)的健康状况。

如果无线振动传感器检测到振动变化超过预定阈值,则会自动触发警报并发送给维护团队成员。根据资产关键性(即对整体生产和运营的影响),决定立即安排维修或更换机械。

通知可以优化维护计划和人工,确保零件可用性,并最终避免资产故障。

A wireless vibration monitoring sensor generates a vibration signal from the machine where it’s mounted, converts and processes it, and then sends the real-time data to a web application. That asset management software lets maintenance teams view and trend data, as well as perform data analysis.

With wireless vibration monitoring, the sensor tracks and records vibration level measurements used to determine the health of rotating machinery such as compressors and pumps (drive motors, driven devices) and belts, gears, shafts, bearings, and other components that make up a mechanical system.

If a wireless vibration sensor detects a change in vibration that exceeds predetermined threshold levels, an alert is triggered automatically and sent to a maintenance team member. Based on the asset criticality, meaning the impact on overall production and operations, a determination is made to immediately schedule a repair or replace the machinery.

The notification enables optimization of maintenance schedules and labor, ensures parts availability, and ultimately avoids asset failure.

测量振动的不同方法

Different Ways to Measure Vibration

振动可以用三种不同的方式测量:位移、速度和加速度。

• 位移是物体从参考点移动的距离。它最适合测量低频。

• 速度是位移随时间的变化率,涵盖广泛的频率范围。它最适合诊断导致磨损和故障的疲劳力。

• 加速度是速度随时间的变化率。它最适合测量非常高的频率。

加速度计是最常见的振动传感器之一,因为它们坚固耐用,并且很容易将加速度转换为速度。

Vibration can be measured in three different ways: displacement, velocity, and acceleration.

• Displacement is the distance an object moves from a reference point. It’s best for measuring low frequencies.

• Velocity is the changing rate of displacement over time and covers a wide range of frequencies. It is best at diagnosing fatigue forces that cause wear and failure.

• Acceleration is the changing rate of velocity over time. It’s best for measuring very high frequencies.

Accelerometers are one of the most common vibration sensors because they’re rugged, and it’s easy to convert the acceleration to velocity.

振动传感器为何如此重要

Why Vibration Sensors Are Important

使用有线和无线传感器测量振动变化已成为工业维护和可靠性计划中必不可少的环节。

当机器意外停机时,成本可能很高。例如,轴不平衡可能导致联轴器损坏,并导致需要更换整个电机。

Using wired and wireless sensors to measure vibration changes has become essential in industrial maintenance and reliability programs.

When a machine goes down unexpectedly, the costs can be high. For instance, a shaft imbalance can cause coupling damage and lead to an entire motor needing to be replaced.

测量振动以尽早发现机器故障:

Measuring Vibration to Catch Machine Faults Early:

• 降低能源成本

• 减少停机时间和人工成本

• 降低维护和更换成本

• 提高安全性

• Lowers energy costs

• Reduces downtime and labor costs

• Decreases maintenance and replacement costs

• Increases safety

设置无线振动传感器

Setting up a Wireless Vibration Sensor

确定适当的振动传感器设置、环境条件和传感器位置对于传感器的正常运行至关重要。根据安装类型、机器类型和软件,一些振动传感器易于设置,配置、调试和安装后即可立即使用。相比之下,其他振动传感器则更为复杂,因此咨询专家通常会有所帮助。

Determining the proper vibration sensor setup, environmental conditions, and sensor location are critical to a properly functioning sensor. Depending on the type of mount, machine type, and software, some vibration sensors are easy to set up and can be used immediately once configured, commissioned, and installed. In contrast, others are more complex, so it’s often helpful to consult an expert.

选择合适的无线振动传感器

Choosing the Right Wireless Vibration Sensor

振动传感器有很多种类型。无线振动监测的选择通常取决于组织的整体运营能力。机器或部件对生产的重要性以及应用将有助于确定需要哪种无线振动传感器。

例如,筛选传感器通常安装在半关键和其他重要机器上。它提供读数以指示存在问题,并让用户知道机器是否需要检查或维护。

分析振动传感器通常用于更关键的资产。这些传感器具有加速度计,可帮助测量数据中看到的幅度和模式的变化。需要高分辨率传感器来提供分析所需数据的详细信息。

There are a number of different types of vibration sensors. Wireless vibration monitoring choices usually depend on an organization’s overall operational capacity. How critical a machine or component is to production and the application will help determine which wireless vibration sensor is needed.

For instance, a screening sensor is usually mounted on semi-critical and other essential machinery. It provides readings to indicate a problem exists and lets users know if the machine needs to be inspected or maintained.

An analysis vibration sensor is generally used on more critical assets. These sensors have accelerometers that help measure changes in amplitude and patterns seen in the data. A high-resolution sensor is needed to provide the detail of the necessary data for analysis.

传感器的设计、尺寸和范围多种多样,因此非常灵活。了解期望测量的数据特征以及任何环境限制有助于确定哪种传感器最适合预期用途。

There are many designs, sizes, and ranges of sensors to choose from, making them highly flexible. Understanding the data characteristics you expect to measure, and any environmental constraints can help decide which one fits the intended use best.

声明:

- 文章转载自PRUFTECHNIK,由爱泽工业翻译,如有侵权,请联系删除!

- 如有偏颇,欢迎指正!

沪公网安备31011002006738号

沪公网安备31011002006738号