带您了解恒位油杯的润滑原理(中英文)

These effective, yet simple, devices explained

这些有效而又简单的设备说明

它们是如何工作的?

How do they work?

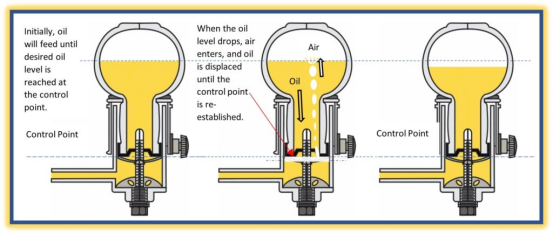

恒定油位润滑是指在润滑油油底壳中保持油位一致。如果因泄漏或使用而造成油损失,油箱将提供一定量的油。该储备将补充润滑油油底壳中的油,直到再次保持原始油位。如果瓶中有储备油,情况就会如此。这种应用已经存在多年,并被世界各地的最终用户和原始设备制造商使用。将一整瓶液体倒置,而不仅仅是倒空,这种概念在某种程度上违背了逻辑。当然,这不是魔术。流体动力学的基本规则在起作用——油置换的功能。根据液位调节机制,瓶中的液体将流出,直到达到要保持的油位。此后,如果油位低于控制点,无论使用哪种油杯,空气都会进入油箱,并向上流动到倒置瓶子顶部空间中,直至油位突破。这些额外的空气将取代瓶子中的液体,直到空气通道不再存在,或控制点液位重新建立。

Constant level lubrication is the concept of maintaining a consistent level of oil in a lubricating sump. If there is any oil loss due to leakage or usage the reservoir of oil will provide a volume of oil. This reserve will replenish oil in the lubricating sump until the original oil level is maintained again. This will be the case if there is reserve oil in the bottle. This application has been around for many years and used by end users and original equipment manufacturers all over the world. The concept of a full bottle of fluid upside down, and not just emptying out, is to somehow defy logic. But, of course, this is not magic. The basic rules of fluid dynamics are at play – a function of oil displacement. The fluid in the bottle will feed out until it reaches the oil level to be maintained, based on the level adjustment mechanism. After that, if the oil breaks below the control point, regardless of which oiler, air will enter the reservoir, traveling up to where it will break in the headspace of the inverted bottle. This additional air will displace fluid out of the bottle until the path of air is no longer present, or when the control point level is re-established.

为什么需要不同类型的恒位油杯?

Why different types of Constant Level Oilers?

有人可能好奇为什么在工厂中看到几种不同类型的油杯?选择特定恒位油杯的原因有很多。以下是一些最常见的原因:

• 设备的设计考虑。

• 油的污染防护。

• 设备和辅助产品符合行业标准。

• 多年来一直如此,没有人会改变它。

关于任何恒位油杯,要了解的主要一点是,它们都完全按照名称所代表的那样工作。无论用户选择哪种油杯,它们都会提供恒定的油位。

You may have wondered why you see several different types of oilers when walking through a plant? There are many reasons for choosing a particular Constant Level Oiler. Here are a couple of the most common:

• design considerations of the equipment it is on.

• contamination protection of the oil.

• equipment and ancillary products are following industry standards.

• that is the way it has been for years, and no one is going to change it.

The main thing to understand about any constant level oiler is that they all do exactly what the name implies. It does not matter which oiler you choose; they will all provide a constant level.

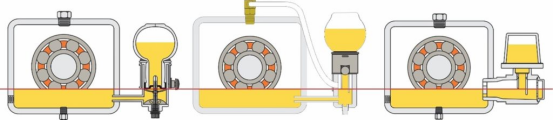

多年来,Trico 一直引领恒位油杯的改革和改进,并由此诞生了一系列产品。

• 原创 Opto-Matic – 行业中最常见的产品,也是一切的起源。

• 塑料 Opto-Matic – 不同行业使用不同的材料。

• 封闭式油杯 – 专为防污染而设计。与外界空气隔绝。

• Watchdog油杯 – 不可调节 – 直接安装在需要维护的油的中心线上。

• Sensei 启用的 Opto-Matic 油杯 – Trico 在恒位润滑方面的最新创新。基于云的油杯监控。

Throughout the years, Trico has led the reform and refinement of constant level oilers, resulting in a family of products.

• The Original Opto-Matic – The most common in industry and the one that started it all.

• The Plastic Opto-Matic – Different materials for different industries.

• The Closed System Oiler – Designed for contamination protection. Closed to outside atmosphere.

• The Watchdog Oiler – Non-adjustable – Installed directly on the centerline of the oil to be maintained.

• Sensei Enabled Opto-Matic Oiler – Trico’s latest innovation in Constant Level Lubrication. Cloud-based oiler monitoring.

使用 Machine Vitals 增强油位监测

Enhancing Oil Level Monitoring with Machine Vitals

Machine Vitals为恒定油位油杯提供了强大的补充,可提前提示与油位过低或过高相关的潜在问题。作为 Sensei IIoT 网络的一部分,这款状态监测设备可跟踪温度、压力、相对湿度、声学和加速度变化等关键参数。通过提供全面的机械健康状况概览,Machine Vitals可确保能够及时解决油位问题并保持最佳设备性能。

Machine Vitals™ offers a powerful complement to constant level oilers by providing early indications of potential issues related to low or high oil levels. As part of the Sensei® IIoT Network, this advanced condition monitoring device tracks critical parameters such as temperature, pressure, relative humidity, acoustics, and acceleratory variance. By delivering a comprehensive overview of machinery health, Machine Vitals™ ensures that you can address oil level concerns promptly and maintain optimal equipment performance.

声明:

- 文章转载自TRICO,由爱泽工业翻译,如有侵权,请联系删除!

- 如有偏颇,欢迎指正!

沪公网安备31011002006738号

沪公网安备31011002006738号