关于球阀 - 相关认证/连接类型/外壳材料/工作原理/类型等(中英文)

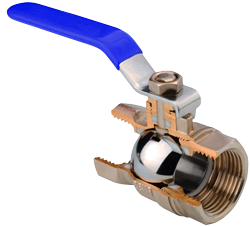

球阀是一种截止装置,使用带孔的旋转球来调节液体或气体的流动。通过将球绕其轴线旋转四分之一圈(90 度),阀门可以打开或关闭,允许介质通过或阻塞。球阀以其使用寿命长而闻名,并且在整个使用过程中提供可靠的密封,即使长时间不使用也是如此。与大多数其他类型的阀门相比,它们对受污染介质的抵抗力更强。

某些类型的球阀也用作控制阀。由于与其他类型的控制阀相比,控制流量的精度相对有限,因此这种用途较少。但是,球阀在这方面有一些优势。例如,即使介质不干净,它们也能保持可靠的密封。

A ball valve is a shut-off device that regulates the flow of a liquid or gas using a rotating ball with a hole. By turning the ball a quarter turn (90 degrees) around its axis, the valve either opens or closes, allowing the medium to pass through or blocking it. Ball valves are known for their long lifespan and provide dependable sealing throughout their use, even when left unused for extended periods. They are more resistant to contaminated media than most other valve types.

Certain types of ball valves are also employed as control valves. This use is less frequent due to the relatively limited precision in controlling flow rates compared to other control valve types. However, ball valves have some advantages in this regard. For instance, they maintain reliable sealing even when the media is dirty.

球阀工作原理和组件

Ball valve working principle & components

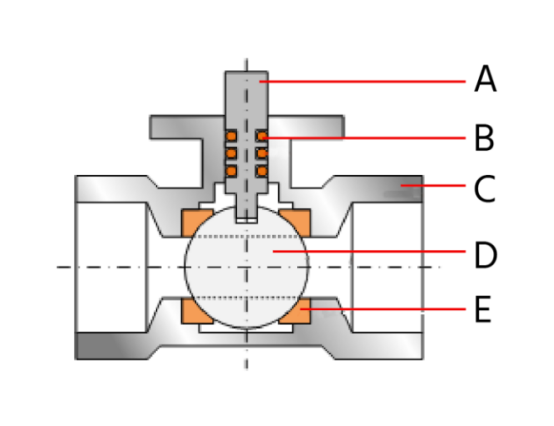

球阀图:阀杆(A)、O 形圈(B)、壳体(C)、球(D)和阀座(E)

Ball valve diagram: stem (A), o-rings (B), housing (C), ball (D), and seat (E)

了解球阀的五个主要部件对于理解球阀的工作原理非常重要。图中球阀的示意图显示了这五个主要部件。

• 阀杆 (A):阀杆将执行器(例如手柄或执行器(电动或气动))连接到球。

• O 形环 (B):阀座上的 O 形环有助于防止泄漏。

• 外壳 (C):外壳支撑阀门的所有内部组件,并保护它们免受应用和环境条件的影响。

• 球 (D):球具有空心孔,当阀门打开时,流体可以通过该孔流动。

• 阀座 (E):阀座支撑并密封球组件。

当阀杆转动四分之一圈时,孔要么打开以允许介质流过,要么关闭以阻止介质流动。球阀的电路功能、外壳组装、球设计和操作类型都会影响其操作,下面将对此进行介绍。

与闸阀等相比,球阀更常用作截止阀。

It is important to know the five main ball valve parts to understand the working principle of a ball valve. The diagram of the ball valve in Figure shows these five main components.

• Valve stem (A): The valve stem connects the actuator (e.g., handle or actuator (electric or pneumatic)) to the ball.

• O-rings (B): O-rings on the valve's seat help prevent leakage.

• Housing (C): The housing supports all the valve's inside components and protects them from application and environmental conditions.

• Ball (D): The ball has a hollow bore through which fluid can flow when the valve is opened.

• Seat (E): The seat supports and seals the ball component.

When the valve stem is turned a quarter-turn the bore is either open to the flow allowing media to flow through or closed to prevent media flow. A ball valve's circuit function, housing assembly, ball design, and operation types all impact its operation and are discussed below.

Ball valves are more popular as a shut-off valve than, for example, the gate valve.

回路功能

Circuit function

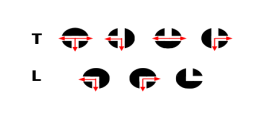

阀门可能有两个、三个甚至四个端口(2 通、3 通或 4 通)。绝大多数球阀都是 2 通的,用杠杆手动操作。阀门打开时,杠杆与管道成一线。在关闭位置,手柄垂直于管道。对于 2 通阀,球阀的流动方向只是从输入到输出。手动操作的球阀可以快速关闭,因此在快速流动的介质中存在水击风险。一些球阀配有传动装置。3 通阀具有 L 形或 T 形孔,这会影响回路功能(流动方向)。因此,可以实现各种回路功能,例如分配或混合流量。90 度球阀有两个端口,它们以 90 度角定位。

The valve may have two, three or even four ports (2-way, 3-way, or 4-way). The vast majority of ball valves are 2-way and manually operated with a lever. The lever is in line with the pipe when the valve is opened. In the closed position, the handle is perpendicular to the pipe. The ball valve flow direction is simply from the input to the output for a 2-way valve. Manually operated ball valves can be quickly closed and therefore there is a risk of water hammer with fast-flowing media. Some ball valves are fitted with a transmission. The 3-way valves have an L-shaped or T-shaped bore, which affects the circuit function (flow direction). As a result, various circuit functions can be achieved such as distributing or mixing flows. A 90-degree ball valve has two ports that are positioned at a 90-degree angle.

壳体组装

Housing assembly

阀壳体的组装可分为三种常用设计:单件式、两件式和三件式壳体。不同之处在于阀门的组装方式,这会影响维护或修理的可能性。每种阀门的操作方式相同。

• 单件式:这是最便宜的变体。包围球的两个部件是压制或焊接的。阀门不能打开进行清洁或维护。这种类型通常用于要求不高的应用。

• 两件式:两件式阀门可以拆卸以进行清洁、维修和检查。通常,零件通过螺纹连接连接。必须将阀门从管道中完全移除才能将两个零件分开。

• 三件式:更昂贵的阀门通常有三个零件。零件通常通过螺栓连接夹在一起。这种实施例的优点是无需将整个阀门从管道中移除即可对阀门进行维修。

The assembly of the valve housing can be divided into three commonly used designs: one-piece, two-piece, and three-piece housings. The difference is how the valve is assembled and this affects the possibilities for maintenance or repair. The operation of the valves is the same in each embodiment.

• One-piece: This is the cheapest variant. The two parts which enclose the ball are pressed or welded. The valves can not be opened for cleaning or maintenance. This type is generally used for low-demanding applications.

• Two-piece: Two-piece valves can be disassembled for cleaning, servicing, and inspection. Often, the parts are connected via a threaded connection. The valve must be completely removed from the pipe in order to separate the two parts.

• Three-piece: More expensive valves often have three pieces. The parts are generally clamped together by bolt connections. The advantage of this embodiment is that the valve can be serviced without removing the entire valve from the pipeline.

锻造球阀

Forged ball valves

锻造球阀是通过在合金和金属仍处于固态时对其进行塑形而制成的。金属和合金通过加热或使用工业尺寸的工具弯曲,这些工具会施加压缩力来弯曲材料。锻造球阀更适合需要高温、高压和其他恶劣条件的工业应用。黄铜和不锈钢等材料可用于制造锻造球阀。在制造过程中,使用模锻机根据球阀设计对金属(或合金)进行加热、压缩、弯曲和塑形。

模具有助于将金属模制成特定形状,而机器则施加足够的压力,迫使金属进入合适的形状。对于尺寸较大的球阀,需要将不同的组件焊接在一起。还可以根据特定需求在阀门上涂上专门的涂层。

Forged ball valves are created by shaping the alloys and metals while they are still in their solid form. The metals and alloys are bent by heating or with industrial-sized tools that deliver compressive forces to bend the materials. Forged ball valves are better suited for industrial applications that require high temperatures, pressures, and other severe conditions. Materials like brass and stainless steel can be used to construct forged ball valves. During the manufacturing process, the metal (or alloy) is heated, compressed, bent, and shaped according to the ball valve design using a die forging machine.

The die helps mold the metal into a specific shape, while the machine applies sufficient pressure that forces the metal to get into the apt shape. For ball valves that are sized bigger, it is necessary to weld different components together. The valves can also be coated with specialized coatings based on specific needs.

锻造球阀的优点

Forged ball valve benefits

• 锻造球阀坚固耐用,可用于高温高压等特别苛刻的情况。

• 锻造工艺降低了球阀对孔隙度、开裂和收缩等问题的敏感性。

• 锻造球阀可以非常快速地适应温度变化;因此,这些阀门适合在多种环境中运行。

• 维护需求低。

• Forged ball valves are strong and durable and can be used in particularly demanding situations that involve high temperatures and pressures.

• The forging process reduces the ball valve’s susceptibility to issues like porosity, cracking, and shrinkage.

• Forged ball valves can adapt to temperature changes very quickly; therefore, these valves are suitable for operation in multiple environments.

• Low maintenance needs.

球阀设计

Ball design

最常见的设计是“浮动球阀设计”。球阀悬浮在介质中,并由两个密封圈固定。一些高质量的阀门采用耳轴球阀设计。球阀的顶部和底部均有支撑,以减轻阀座上的负载。

• 浮动:大多数球阀都有浮动球阀。球阀由阀座支撑。

• 耳轴:直径大、工作压力高的阀门(例如 DN > 100 毫米和 30 巴)通常在其设计中采用球阀支撑。具体而言,球阀的底部和顶部均有支撑,以减轻阀座上的负载。耳轴阀的操作扭矩通常较低。

穿过球阀的孔可能具有不同的轮廓,例如全孔、缩径或 V 形。

• 缩径:大多数球阀的孔径都缩径。因此,阀门会在系统中引入摩擦损失。与其他类型的阀门相比,这些损失仍然相对较小。一体式球阀几乎总是缩径的。

• 全径:全径阀门的内径与管道相同。优点是没有额外的摩擦损失,并且系统在机械上更容易清洁(清管)。缺点是球和壳体比标准缩径四分之一转阀更大。因此成本略高,并且对于许多应用来说,这不是必需的。它们也称为全通径球阀。

• V 形:球或阀座上的孔具有“V”形轮廓。因此,可以通过旋转球更精确地控制所需的流量。通过优化轮廓,可以接近线性流动特性。

The most common design is the "floating ball design." The ball is suspended in the media and held in place by two sealing rings. Some high-quality valves have a trunnion ball design. The ball is supported at the top and bottom to reduce the load on the valve seats.

• Floating: The majority of ball valves have a floating ball. The ball is supported by the valve seats.

• Trunnion: Valves with large diameters and high operating pressures (for example DN > 100 mm and 30 bar), often incorporate ball valve support in their design. Specifically, the ball is supported on the bottom and top to reduce the load on the seat rings. The operating torque is generally lower for trunnion valves.

The hole through the ball may have different profiles such as a full bore, reduced bore or V-shaped.

• Reduced bore: Most ball valves have a reduced bore. As a result, the valve introduces friction losses in the system. These losses are still relatively small compared to other types of valves. One-piece ball valves are almost always reduced bore.

• Full bore: Full bore valves have the same bore diameter as the pipe. The advantage is that there are no extra friction losses and that the system is mechanically easier to clean (pigging). The downside is that the ball and the housing are bigger than a standard reduced bore quarter-turn valve. The cost is therefore slightly higher, and for many applications, this is not required. They are also called full port ball valves.

• V-shaped: The hole in the ball or the valve seat has a 'V' shaped profile. As a result, the desired flow rate can be controlled more precisely by rotating the ball. By optimizing the profile, a linear flow characteristic can be approached.

球阀手柄

Ball valve handle

手柄与阀杆相连,能够将阀门从打开位置或关闭位置(90 度)转动。如果安装正确,当手柄与管道平行时,阀门将打开,当手柄与管道垂直时,阀门将关闭。注意手柄方向对于直观地了解球阀是打开还是关闭非常重要。还有其他球阀手柄类型,如可锁定手柄或球阀手轮。它们的操作方式与名称所示一致。如果有更大的球阀或需要额外的扭矩来打开或关闭阀门,则可能需要球阀手柄延长器。如果手柄断裂、放置错误或正在将自动球阀转换为手动球阀,可以购买球阀替换手柄。

The handle is connected to the valve stem and is capable of turning the valve from the open or closed position (90 degrees). If installed correctly, the valve will be open when the handle is parallel to the pipe and closed when the handle is perpendicular to the pipe. Taking note of the handle direction is important to visually know if the ball valve is open or closed. There are additional ball valve handle types, like lockable handles or ball valve handwheels. These operate as their names suggest. If you have a bigger ball valve or need additional torque to open or close the valve, a ball valve handle extension may be required. If your handle breaks, is miss-placed or you are converting an automatic ball valve to a manual one, you can buy ball valve replacement handles.

通风球阀

Vented ball valves

通风球阀的设计与标准 2 通球阀几乎相同。主要区别在于,出口在关闭位置时会向环境通风。这是通过在球和阀体上钻一个小孔来实现的。当阀门关闭时,这些孔与出口对齐并释放压力。这在压缩空气系统中尤其有用,因为减压可以提供更安全的工作环境。直观上看,这些阀门看起来像 2 通球阀,但实际上,由于用于通风的小钻孔,它们是 3/2 通的。

Vented ball valves look almost the same as the standard 2-way ball valves when it comes to their design. The main difference is that the outlet port vents to the environment in the closed position. This is achieved by a small hole that is drilled in the ball and in the valve body. When the valve closes, the holes line up with the outlet port and release the pressure. This is especially useful in compressed air systems where depressurization provides a safer working environment. Intuitively these valves look like 2-way ball valves while in fact, they are 3/2-way due to the small borehole for venting.

自动球阀

Automatic ball valves

气动球阀(左)、电动球阀(中)、ISO-顶部球阀(右)

Pneumatic ball valve (left), electric ball valve (middle), ISO-top ball valve (right)

有些阀门可以安装电动或气动执行器,而不是手动操作来打开或关闭阀门。它们直接连接到阀杆,能够将其旋转四分之一圈。阀门和执行器之间最常见的法兰连接是 ISO 5211 标准。上图显示了准备连接到执行器的 ISO 5211 顶部的示例。通过使用执行器,可以远程或通过控制器控制球阀,以便将其用作自动关闭装置。弹簧驱动球阀,也称为弹簧加载阀或弹簧回位球阀,使用弹簧在断电情况下打开/关闭阀门,然后使用执行器将球阀保持在开/关位置。它们用于节能应用或出于故障安全原因。

Instead of a manual handle operation to turn the valve on or off, some valves can be fitted with an electric or pneumatic actuator. They connect directly to the valve stem and are capable of turning it a quarter turn. The most common flange connection between the valve and actuator is the ISO 5211 standard. Figure 4 shows an example of an ISO 5211 top ready to be connected to an actuator. By using an actuator, you can control your ball valve remotely or through a controller so that it can be used as an automatic shut-off. A spring-actuated ball valve, also called a spring-loaded valve or a spring return ball valve, uses a spring to open/close the valve in a power-off scenario and an actuator to then hold the ball valve in the on/off position. These are used for energy conservation applications or for fail-safe reasons.

控制电动执行器有多种不同的方法:

• 2 点控制(也称为开-关或开-关电路)除了电源线外还使用一根控制线。一旦控制线通电,阀门就会电动打开。如果控制线断电,阀门就会关闭(电动或通过弹簧关闭)。

• 3 点控制使用两根控制线:一根用于逆时针旋转球,一根用于顺时针旋转球。根据应用情况,可以选择最合适的控制。

某些电动执行器还可以提供调节控制,将球阀定位在 0-100% 的开/关之间。

There are several different ways to control an electric actuator:

• A 2-point control (also called an Open-Close or On-Off circuit) uses one control wire in addition to the power wires. Once the control wire is energized, the valve opens electrically. If the control wire is unpowered, the valve closes (electrically or by means of a spring).

• A 3-point control uses two control wires: one for rotating the ball counterclockwise, and one for rotating the ball clockwise. Depending on the application, the most appropriate control can be chosen.

Certain electric actuators can also provide modulation control, which will position the ball valve between 0-100% open/closed.

球阀外壳材料

Ball valve housing materials

最常见的外壳材料是黄铜、不锈钢和 PVC(聚氯乙烯)。球通常由镀铬钢、镀铬黄铜、不锈钢或 PVC 制成。阀座通常由特氟龙制成,但也可以由其他合成材料或金属制成。

The most common housing materials are brass, stainless steel and PVC (PolyVinyl Chloride). The ball is usually made of chrome plated steel, chrome plated brass, stainless steel or PVC. The seats are often made of Teflon, but could also be made of other synthetic materials or metals.

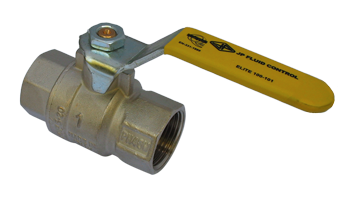

黄铜球阀

Brass ball valve

黄铜的球阀最常见。黄铜是铜和锌的合金,具有良好的机械性能。黄铜阀门用于(饮用)水、天然气、油、空气和许多其他介质。氯化物溶液(例如海水)或去离子水可能会导致脱锌。脱锌是一种腐蚀形式,其中锌从合金中去除。这会产生多孔结构,机械强度大大降低。黄铜外壳是空气球阀或管道球阀的理想选择。

Brass has the largest market share. Brass is an alloy of copper and zinc and has good mechanical properties. Brass valves are used for (drinking) water, gas, oil, air and many other media. Chloride solutions (e.g. seawater) or demineralized water may cause dezincification. Dezincification is a form of corrosion in which zinc is removed from the alloy. This creates a porous structure with a greatly decreased mechanical strength. A brass housing is ideal for an air ball valve or a ball valve for plumbing.

不锈钢球阀

Stainless steel ball valve

不锈钢用于腐蚀性介质和腐蚀性环境。因此,它们经常用于海水、游泳池、渗透装置、高温和许多化学品中。大多数不锈钢是奥氏体。304 和 316 型是最常见的,316 具有最好的耐腐蚀性。304 有时被称为 18/8,因为含有 18% 的铬和 8% 的镍。316 含有 18% 的铬和 10% 的镍(18/10)。不锈钢阀门通常需要比黄铜或 PVC 阀门更高的操作扭矩。当不锈钢阀门由电动或气动执行器操作时,必须考虑到这一点。

Stainless steel is used for corrosive media and aggressive environments (Figure 6). They are therefore often used in seawater, swimming pools, osmosis installations, with high temperatures, and many chemicals. Most stainless steel is austenitic. Type 304 and 316 are the most common, 316 has the best corrosion resistance. 304 is sometimes referred to as 18/8 because of 18% chromium and 8% nickel. 316 has 18% chromium and 10% nickel (18/10). Stainless steel valves usually require a higher operating torque than for example brass or PVC valves. This must be taken into account when a stainless steel valve is operated by an electric or pneumatic actuator.

PVC 球阀

PVC ball valve

PVC 通常价格较低(ISO 顶阀除外),广泛应用于灌溉、供水和排水或腐蚀性介质。PVC 代表聚氯乙烯。PVC 可耐受大多数盐溶液、酸、碱和有机溶剂。PVC 不适用于高于 60°C 的温度,也不耐受芳香烃和氯化烃。PVC 不如黄铜或不锈钢坚固,因此 PVC 球阀的压力等级较低。

PVC often has a lower price (except for ISO-top valves) and is widely used in irrigation, water supply and drainage or corrosive media (Figure 7). PVC stands for polyvinyl chloride. PVC is resistant to most salt solutions, acids, bases, and organic solvents. PVC is not suitable for temperatures higher than 60 °C, and is also not resistant to aromatic and chlorinated hydrocarbons. PVC is not as strong as brass or stainless steel, therefore PVC ball valves have lower pressure rating.

黄铜、不锈钢和 PVC 球阀

Brass vs stainless steel vs PVC ball valve

密封件和 O 形圈

Seals and o-rings

大多数阀座由 PTFE(特氟隆)制成。PTFE 代表聚四氟乙烯。这种材料具有非常好的耐化学性和高熔点(~327 °C)。除此之外,摩擦系数极低。PTFE 的一个小缺点是材料会蠕变,这会导致密封性随时间推移而恶化。除此之外,PTFE 的热膨胀系数相当高。解决此问题的方法是使用弹簧对特氟隆密封件施加恒定压力,例如杯形弹簧。其他常用的密封材料是 PTFE 和聚酰胺(尼龙)。阀座材料越硬,保持正确密封就越困难。对于某些无法使用软材料的应用,例如在非常高的温度下,使用金属或陶瓷阀座。

Most valve seats are made of PTFE (Teflon). PTFE stands for PolyTetraFluorEthylene. This material has a very good chemical resistance and a high melting point (~327 °C). Besides that, the friction coefficient is extremely low. A small disadvantage of PTFE is that the material shows creep, which can cause a deterioration of the sealing over time. Besides that, PTFE has a rather high thermal expansion coefficient. A solution for this problem is to use a spring in order to apply constant pressure on the Teflon seal, like for example a cup spring. Other popular sealing materials are PTFE and Polyamide (Nylon). The harder the material of the valve seat is, the more difficult it is to maintain proper sealing. For some applications in which soft materials are not possible to use, for example with very high temperatures, metal or ceramic valve seats are used.

高压球阀

High-pressure ball valves

顾名思义,高压球阀在高流体压力下工作,大约 500-700 巴。当阀门尺寸变大时,它可以处理的压力会降低,反之亦然。这些阀门非常耐用,用于具有相同压力负载的管道系统中。手动高压球阀可以通过将杠杆旋转 90 度来操作。电动高压球阀通过电信号模拟其操作。阀门的构造采用碳钢和不锈钢 316 等材料。应使用双层或其他高弹性材料来构造阀门部件,如阀杆、球和阀座环。这有助于承受阀门的高压额定值和执行器的最大允许阀杆扭矩。

高压球阀有以下几种连接类型:

• 英国标准管平行 (BSPP) 螺纹

• 国家管螺纹 (NPT) 螺纹

• 压缩型 (DIN 2353/ISO 8434-1)

• 焊接端

高压球阀用于那些需要大量储存流体并根据要求使用的行业,如水上乐园、供水厂和化学工业。

As the name suggests, a high-pressure ball valve works under high fluid pressure, approximately 500-700 bars. When the valve size gets bigger, it reduces the pressure it can handle, and vice versa. These valves are highly durable and used in piping systems with connections at the same pressure load. Manual-type high-pressure ball valves can be operated by turning the lever 90 degrees. Motorized high-pressure ball valves are simulated through an electric signal for their operation. Materials like carbon steel and stainless steel 316 are used for the valve’s construction. Duplex or other highly resilient materials should be used to construct valve parts like stem, ball, and seat rings. This helps withstand the valve’s high-pressure ratings and the actuator's maximum allowable stem torque.

High-pressure ball valves are available in the following connection types:

• British standard pipe parallel (BSPP) threaded

• National pipe thread (NPT) threaded

• Compression type (DIN 2353/ISO 8434-1)

• Welding end

High-pressure ball valves are used in those sectors where the fluid is stored in large quantities and used according to their requirements, like water parks, water distribution plants, and chemical industries.

液压球阀

Hydraulic ball valves

液压球阀专为液压和加热系统设计,因为它们具有高工作压力等级和耐液压油和加热油性。这些阀门由钢或不锈钢制成。除了这些材料外,阀座也使液压阀适用于高工作压力。这些阀门的阀座由聚甲醛 (POM) 制成,适用于高压和低温应用。液压球阀的最大工作压力超过 500 bar,最高温度可达 80 °C。

Hydraulic ball valves are specially designed for hydraulic and heating systems due to their high operating pressure rating and hydraulic and heating oil resistance. These valves are made of either steel or stainless steel. Besides these materials, the seats also make hydraulic valves suitable for high operating pressure. The seats of these valves are made of polyoxymethylene (POM), which is suitable for high-pressure and low-temperature applications. The maximum operating pressure of hydraulic ball valves goes above 500 bar while the maximum temperature goes up to 80 °C.

球阀连接类型

Ball valve connection types

球阀可以通过多种方式连接到管道,使其适用于各种应用。以下是其常见的连接类型:

• 标准(螺纹):标准球阀由壳体、阀座、球和用于球旋转的杠杆组成。它们包括具有两个、三个和四个端口的阀门,这些端口可以是内螺纹或外螺纹或两者的组合。

• 法兰:端口通过法兰连接到管道系统,法兰通常按照特定标准设计。这些阀门提供高流量,因为它们通常具有全孔设计。

Ball valves can be connected to pipes in several ways, making them versatile for various applications. These are their common connection types:

• Standard (threaded): Standard ball valves consist of the housing, seats, ball and lever for ball rotation. They include valves with two, three, and four ports which can be female or male threaded or a combination of those.

• Flanged: The ports are connected to a piping system via flanges that are usually designed in accordance with a certain standard. These valves provide a high flow rate since they typically have a full-bore design.

认证

Approvals

对于某些应用,需要或必须获得认证。饮用水和天然气是最常见的。选择经过认证的球阀,可确保产品满足重要的安全要求。

For certain applications, approvals are desired or required. Drinking water and gas are the most common. Choosing a certified ball valve, assures that the product meets important safety requirements.

饮用水

Drinking water

这些球阀适用于饮用水应用,并已获得 WRAS、KIWA 或 DVGW 认证。如果与储水箱一起使用,它们通常与浮动开关配合使用以监测水位。此外,水球阀关闭功能可确保在必要时快速安全地停止水流。

These ball valves are suitable for drinking water applications and have a WRAS, KIWA or DVGW approval. If being used with a water holding tank, they often work in connection with a float switch to monitor water level. Additionally, the water ball valve shut off feature ensures a quick and secure means to stop water flow when necessary.

燃气

Gas

这些球阀已获准用于燃气设备。

These ball valves are approved for gas appliances.

声明:

- 文章转载自TAMESON,由爱泽工业翻译,如有侵权,请联系删除!

- 如有偏颇,欢迎指正!

沪公网安备31011002006738号

沪公网安备31011002006738号