止回阀 - 工作原理/类型/材质/选型/应用等(中英文)

止回阀允许液体和空气仅朝一个方向流动。止回阀的主要目的是防止系统中的回流。止回阀是解决潜在回流问题的廉价、有效且简单的解决方案。如果流体受到污染,回流可能会造成问题,因为它会污染上游介质。例如,下水道管线将有一个止回阀,以确保废液可以离开系统(例如住宅管道系统),但不能重新进入。

A check valve allows liquid and air to flow in only one direction. The primary purpose of a check valve is to prevent backflow in the system. Check valves are inexpensive, effective, and easy solutions to the potential issue backflow. Backflow can cause a problem if the flow is contaminated because it can contaminate upstream media. For example, a sewer line will have a non-return valve to ensure that waste can leave a system (e.g., residential plumbing system) but cannot re-enter.

止回阀的工作原理

How does a check valve work

开启压力

Cracking pressure

止回阀需要入口和出口之间有最小压差才能打开,从而允许介质流过。阀门打开时的最小上游压力称为止回阀的开启压力。具体开启压力会根据阀门的设计和尺寸而变化,因此请确保系统压力可以产生所选止回阀的开启压力。

A check valve requires a minimum pressure differential between the inlet and outlet to open, allowing media to flow through it. This minimum upstream pressure at which the valve opens is called the check valve's cracking pressure. The specific cracking pressure changes based on the valve design and size, so ensure that the system's pressure can generate the cracking pressure of the chosen check valve(s).

关闭

Closing

如果上游压力低于开启压力或存在背压(流体试图从出口流向入口),单向止回阀将关闭。通常,止回阀有一个闸板、球、隔膜或圆盘压在密封件上以关闭阀门并阻止流动。重力或弹簧可以协助关闭过程。

If the upstream pressure falls below the cracking pressure or there is back pressure (flow attempting to move from the outlet to the inlet), the one way check valve will close. Typically, check valves have a gate, ball, diaphragm, or disc pressed against a seal to close the valve and

block flow. Gravity or a spring can assist in the closing process.

安装方向

Installation orientation

由于单向阀只允许一个方向的流动,因此了解正确的安装方向至关重要。通常,阀门外壳上的箭头指示流动方向。如果没有箭头,请检查阀门以确保其安装在预期的流动方向上。如果阀门安装反了,介质就无法在系统中流动,由此产生的压力积聚可能会造成损坏。

As a one-way valve only allows flow in one direction, knowing the correct installation orientation is crucial. Typically, an arrow on the valve's housing indicates the flow direction. If there isn't an arrow, examine the valve to ensure it is installed in the intended flow direction. If the valve is installed backward, the media cannot move through the system, and the resulting pressure build-up can cause damage.

常开和常闭止回阀

Normally open and normally closed check valves

常开止回阀允许介质自由流动,但在发生回流时会切断流动。常闭止回阀会阻止介质流过,直到破裂压力积聚,此时阀门打开。

A normally open check valve allows the medium to flow freely but shuts off the flow in case of backflow. A normally closed check valve prevents the flow of media through it until the cracking pressure builds up, at which point the valve opens.

止回阀类型

Check valve types

止回阀的操作方式根据其设计而不同。最常见的止回阀是弹簧式直列止回阀。

Check valves operate differently depending on their design. The most common check valve is a spring-loaded in-line check valve.

弹簧式直通止回阀

Spring-loaded in-line check valve

直通式弹簧式止回阀很常见,易于理解,设计简单。图 2 显示了弹簧式直通止回阀处于打开和关闭位置的情况。箭头表示流动方向。当流体进入阀门的输入端口时,它应该具有足够的压力(力)来克服开启压力和弹簧力。压力推动阀瓣(图 2 标记为 B),打开孔口并允许流体通过阀门。当输入压力不再足够高或有足够的背压时,背压和弹簧(图 2 标记为 C)将阀瓣推向孔口并密封阀门。弹簧和阀瓣的短行程距离允许快速关闭反应时间。弹簧止回阀设计还可以防止管路中的压力激增,从而防止水锤。

常见的弹簧式直列止回阀类型也称为:

• 喷嘴止回阀

• 提升式止回阀

• 轴向止回阀

• 过流止回阀

• 静音止回阀

• 防水锤止回阀

In-line spring-loaded check valves are common, easy to understand, and have a simple design. Figure 2 shows a spring-loaded in-line check valve in the open and closed positions. The arrows indicate flow direction. When flow enters the input port of the valve, it should have enough pressure (force) to overcome the cracking pressure and the spring force. The pressure pushes the disc (Figure 2 labeled B), opening the orifice and allowing flow through the valve. When the input pressure is no longer high enough, or there is enough back pressure, the back pressure and spring (Figure 2 labeled C) push the disc against the orifice and seal the valve shut. The spring and the short travel distance for the disc allow for a quick reaction time for closing. The spring check valve design also prevents pressure surges in the line, preventing water hammer.

Common types of spring-loaded in-line check valves are also called:

• nozzle check valves

• poppet check valves

• axial check valves

• excess flow check valves

• silent or quiet check valves

• anti-water hammer check valves

弹簧加载 Y 型止回阀

Spring-loaded Y-check valve

弹簧加载 Y 型止回阀的工作原理与直列弹簧加载止回阀类似。不同之处在于弹簧和可移动阀瓣呈一定角度放置。这形成了一个“y”形,因此得名。它的工作原理与直列阀相同,但由于可移动部件呈一定角度,因此可以在阀门连接到系统时对其进行检查和维修。这些阀门更大,在系统内占用更多空间。

Spring-loaded y-check valves operate similarly to in-line spring-loaded check valves. The difference is that the spring and movable disc are positioned at an angle. This creates a ‘y’ shape, hence the name of the valve. It works the same way as an in-line valve, but since the moveable components are at an angle, they can be inspected and serviced while the valve is connected to the system. These valves are larger and take up more room within the system.

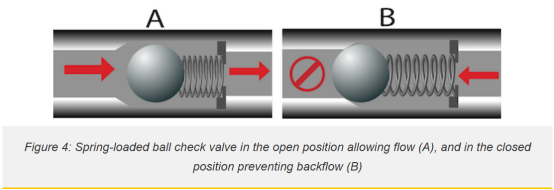

球形止回阀

Ball check valve

球形止回阀使用自由浮动或弹簧加载的球,该球位于密封座上以关闭孔口。密封座通常呈锥形,以将球引导到阀座中并形成正密封,从而阻止反向流动。当入口侧的流体压力超过开启压力时,球会从阀座上移开,从而允许流动。当入口压力不超过开启压力或存在背压时,球将通过背压或弹簧关闭,从而有效地关闭孔口。真正的联合球形止回阀可以轻松拆卸和更换球,无需购买新阀门。

A ball check valve uses a free-floating or spring-loaded ball that rests on the sealing seat to close the orifice. The sealing seat is normally conically tapered to guide the ball into the seat and create a positive seal, thereby stopping reverse flow. When the pressure of the fluid in the inlet side exceeds the cracking pressure, the ball is dislodged from its seat, which permits flow. When the inlet pressure doesn’t exceed the cracking pressure, or there is back pressure, the ball will close with the back pressure or via the spring, effectively closing the orifice. True union ball check valves allow for easy removal and replacement of balls, eliminating the need to buy a new valve.

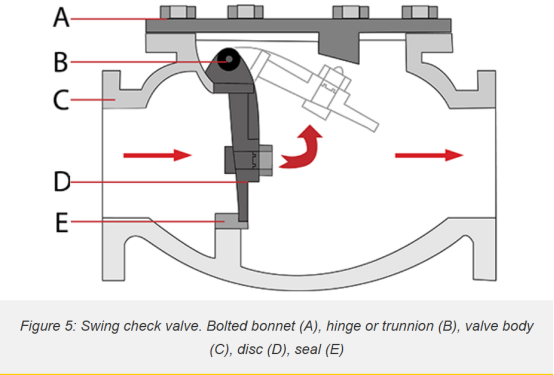

旋启式止回阀

Swing check valve

旋启式止回阀又称为“倾斜阀瓣”或“挡板”止回阀。它们在铰链(或耳轴)上有一个阀瓣,阀瓣会随着入口压力摆动打开。当入口压力降低或出现回流时,阀瓣会摆动关闭。如果没有弹簧协助关闭,则必须考虑安装方向,以确保阀瓣在重力作用下摆动关闭。图 5 显示了旋启式止回阀的示例。

Swing check valves are called ‘tilting-disc’ or ‘flapper’ check valves. They have a disc on a hinge (or trunnion) that swings open with an inlet pressure. The disc swings shut as the inlet pressure decreases or if there is backflow. If there is no spring to assist in closing, mounting orientation is important to consider to ensure that the disc swings shut with gravity. Figure 5 shows an example of a swing check valve.

底阀

Foot valve

底阀是一种与入口侧的过滤器组合的止回阀。过滤器可防止杂物进入止回阀,以免堵塞或损坏下游设备。由于该阀的入口没有连接点,因此安装在一段管道的末端。底阀中常见的止回阀类型是直列弹簧辅助止回阀或直列球形止回阀。它们通常安装在水井、油箱或任何其他吸入管线位于泵下方的应用的泵吸入管线末端。它们可以保持泵处于启动状态,防止液体虹吸回流,并防止杂物进入管线。图 6 显示了底阀的示例。

A foot valve is a check valve combined with a strainer on the inlet side. The strainer prevents debris that could clog or damage something downstream from entering the check valve. This valve is installed at the end of a section of piping as its input doesn't have a connection point. Common check valve types included in a foot valve are in-line spring assisted or an in-line ball check valve. They are typically installed at the end of a pump suction line of a water well, fuel tank, or any other application where the suction line is situated below the pump. They can keep pumps primed, prevent liquid from siphoning back, and keep debris out of the line. Figure 6 shows an example of a foot valve.

止回阀材质

Check valve materials

不锈钢止回阀

Stainless steel check valve

不锈钢止回阀以其出色的耐腐蚀、耐热和耐低温性能而闻名,是苛刻环境的选择。它们具有出色的机械性能,包括高强度和耐用性,有助于延长使用寿命。这些阀门非常适合涉及高温和高压的应用,例如工业加工、化工厂以及石油和天然气工业。

不锈钢止回阀有多种等级,最常见的是 304 和 316。316 级不锈钢具有增强的抗氯化物和其他腐蚀性物质的能力,使其适用于海洋和沿海应用。

虽然不锈钢止回阀具有出色的性能,但对于不需要如此高耐用性或耐性的应用,它们可能不是最具成本效益的解决方案。在这种情况下,PVC 或黄铜等替代材料可能更经济。

主要特点

• 耐腐蚀性:对各种腐蚀介质具有出色的耐受性,包括酸、碱和氯化物。

• 耐高温性:能够承受极端温度,从 -25 °C 到 200 °C(-13 °F 到 392 °F)的高温和低温。

• 机械强度:高强度和耐用性,适用于高达 64 bar(928 psi)的高压应用。

• 多功能性:有各种等级可供选择,以满足特定的应用要求。

应用

• 工业加工

• 化工厂

• 石油和天然气工业

• 海洋和沿海环境

• 高温高压系统

Stainless steel check valves are renowned for their superior resistance to corrosion, heat, and low temperatures, making them ideal for demanding environments. They exhibit excellent mechanical properties, including high strength and durability, contributing to their long service life. These valves are well-suited for applications involving high temperatures and pressures, such as in industrial processing, chemical plants, and oil and gas industries.

Stainless steel check valves are available in various grades, with 304 and 316 being the most common. Grade 316 stainless steel offers enhanced resistance to chlorides and other corrosive substances, making it suitable for marine and coastal applications.

While stainless steel check valves provide exceptional performance, they may not be the most cost-effective solution for applications that do not require such high durability or resistance. In such cases, alternative materials like PVC or brass may be more economical.

Key Features

• Corrosion resistance: Excellent resistance to a wide range of corrosive media, including acids, alkalis, and chlorides.

• Temperature tolerance: Capable of withstanding extreme temperatures, both high and low from -25 °C to 200 °C (-13 °F to 392 °F).

• Mechanical strength: High strength and durability, suitable for high-pressure applications up to 64 bar (928 psi).

• Versatility: Available in various grades to meet specific application requirements.

Applications

• Industrial processing

• Chemical plants

• Oil and gas industries

• Marine and coastal environments

• High-temperature and high-pressure systems

PVC(聚氯乙烯)止回阀

PVC (Polyvinyl Chloride) check valve

PVC 止回阀经常用于灌溉和水管理系统。它们对大多数腐蚀性介质(如海水、酸、碱、氯化物溶液和有机溶剂)具有耐腐蚀性。但是,它们对芳香烃和氯化烃并非免疫,并且通常最高耐温约为 60°C。

主要特点

• 耐腐蚀性:对各种腐蚀性介质具有出色的耐受性,包括海水、酸、碱和氯化物溶液。

• 耐高温性:能够承受高达 60°C (140°F) 的温度。

• 机械强度:强度足以满足低压至中压应用。

• 多功能性:适用于各种水管理和灌溉系统。

应用

• 灌溉系统

• 水管理系统

• 涉及非芳香烃和非氯化烃的化学加工

• 废水处理

PVC check valves are frequently used in irrigation and water management systems. They are corrosion-resistant to most corrosive media like seawater, acids, bases, chloride solutions, and organic solvents. However, they are not immune to aromatic and chlorinated hydrocarbons and typically have a max temperature resistance of around 60 °C.

Key features

• Corrosion resistance: Excellent resistance to a wide range of corrosive media, including seawater, acids, bases, and chloride solutions.

• Temperature tolerance: Capable of withstanding temperatures up to 60 °C (140°F).

• Mechanical strength: Adequate strength for low to moderate pressure applications.

• Versatility: Suitable for a variety of water management and irrigation systems.

Applications

• Irrigation systems

• Water management systems

• Chemical processing involving non-aromatic and non-chlorinated hydrocarbons

• Wastewater treatment

黄铜止回阀

Brass check valve

黄铜止回阀非常适合空气、水、油或燃料应用。但是,它们不耐海水、纯净水或氯化水。与不锈钢相比,黄铜的耐热性和耐腐蚀性较差,通常用于低压应用。

主要特点

• 耐腐蚀性:中等耐腐蚀性,但不适用于海水、纯净水或氯化水。

• 耐高温性:有限的耐高温性,通常适用于低温应用。

• 机械强度:强度足以满足低压应用。

• 多功能性:适用于涉及空气、水、油或燃料的各种应用。

应用

• 低压系统

• 家用水系统

• 燃油管路

• 空气压缩机

Brass check valves are excellent for air, water, oil, or fuel applications. However, they are not resistant to seawater, purified water, or chlorinated water. Compared to stainless steel, brass is less resistant to heat and corrosion and is typically used for applications with low pressure.

Key features

• Corrosion resistance: Moderate resistance to corrosion, but not suitable for seawater, purified water, or chlorinated water.

• Temperature tolerance: Limited temperature tolerance, generally suitable for low-temperature applications.

• Mechanical strength: Adequate strength for low-pressure applications.

• Versatility: Suitable for a variety of applications involving air, water, oil, or fuel.

Applications

• Low-pressure systems

• Domestic water systems

• Fuel lines

• Air compressors

选择标准

Selection criteria

在为某一应用选择止回阀时,需要考虑以下标准:

• 材料与介质的兼容性

• 连接点的管线尺寸

• 最大压力和开启压力要求

• 安装方向水平或垂直

• 外壳尺寸

• 检查和维修的可达性需求

• 温度(外部和介质)

Check valves have the following criteria to consider when selecting one for an application:

• Material compatibility with the medium

• Line size for connection points

• Max pressure and cracking pressure requirement

• Installation orientation horizontal or vertical

• Envelope dimensions

• Accessibility needs for inspections and repairs

• Temperature (external and media)

应用

Applications

由于止回阀的功能,它们通常在各种应用中用于以下四个不同原因之一:

• 保护下游设备免受回流损坏

• 防止因反向流动而造成的污染

• 防止虹吸

• 保持真空密封

由于其功能,它们几乎用于所有行业。它们用于常见的家用电器,如洗碗机、洗衣机和废水管线。对于工业用途,它们用于锅炉、熔炉、气体系统、泵送应用或真空系统。它们还经常用作水和二氧化碳管线上的水族馆止回阀。此外,微型止回阀是一种流行的选择,因为空间有限,但可靠的操作是必不可少的。两种最常见的止回阀应用是水和空气,下面将更深入地讨论它们。

Due to how check valves function, they are typically used for one of four different reasons in various applications:

• To protect equipment downstream from backflow damage

• To prevent contamination due to reverse flow

• To prevent siphoning

• To keep a vacuum seal

Due to their function, they are used in almost every industry. They are used on common household appliances, like dishwashers, washing machines, and wastewater lines. For industrial purposes, they are used on boilers, furnaces, gas systems, pumping applications, or vacuum systems. They are also frequently used as aquarium check valves on water and CO2 lines. Also, a miniature check valve is a popular choice where the space is limited, yet a reliable operation is essential. Two of the most common check valve applications are for water and air, which are discussed in more depth below.

水用止回阀

Check valves for water

水用止回阀用于多种水应用,如饮用水和废水。这些阀门简称为单向水阀。用于饮用水应用的管道止回阀可确保没有任何环境介质(阀门出口侧)可以随安全、清洁的饮用水进入系统并污染系统。对于废水应用,它们可确保废水不会重新进入系统并导致溢流或其他污染。对于水泵应用,通常使用底阀来确保没有杂物进入管道并保持内部压力以用于启动目的。污水泵止回阀可确保在泵关闭时,排出的水不会因重力而回流到污水泵中。

A water check valve is used in numerous water applications, like drinking water and wastewater. These valves are simply called one-way water valves. Plumbing check valves for drinking water applications ensure that no environmental media (outlet side of the valve) can enter the system with the safe, clean drinking water and contaminate it. For wastewater applications, they ensure that the wastewater cannot re-enter the system and cause an overflow or additional contamination. For water pumping applications, a foot valve is often used to ensure no debris enters the line and keep internal pressure for priming purposes. Sump pump check valves ensure that the discharged water does not come back into the sump pump with gravity when the pump is turned off.

气动止回阀

Pneumatic check valve

气动止回阀或空气止回阀允许气流通过并防止气流流出。它们通常简称为单向空气阀。最常见的应用是空气压缩机。气动止回阀允许压缩机保持某些部件加压,而其他部件减压。它们可以位于空气接收器、排气管上,或作为活塞压缩机入口和出口侧的活塞止回阀。

A pneumatic check valve, or air check valve, allows airflow and prevents it from going out. They are often simply called one-way air valves. The most common application is for an air compressor. A pneumatic check valve allows the compressor to keep certain parts pressurized and other parts de-pressurized. They can be located on an air receiver, discharge pipe, or as a piston check valve on the piston compressor's inlet and outlet sides.

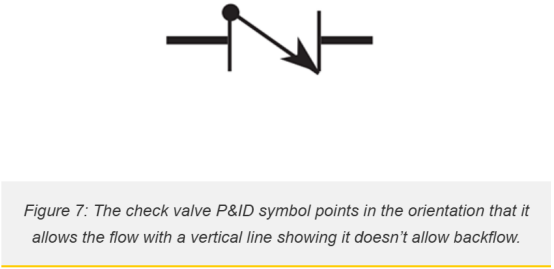

止回阀符号

Check valve symbols

止回阀的 P&ID 符号如图 7 所示。

The P& ID symbol for check valves is shown in Figure 7.

声明:

- 文章转载自TAMESON,由爱泽工业翻译,如有侵权,请联系删除!

- 如有偏颇,欢迎指正!

沪公网安备31011002006738号

沪公网安备31011002006738号