什么是阳离子电导率?为什么它很重要?(中英文)

在公用事业行业,阳离子电导率测量可帮助工厂识别小问题,以便工厂人员能够在问题发展成重大并发症之前解决问题。

In the utility industry, cation conductivity measurements help plants identify minor problems so plant personnel can remedy the issues before they become major complications.

什么是阳离子电导率?它是如何工作的?

What is cation conductivity, and how does it work?

阳离子电导率是监测蒸汽或水样中污染物的最佳方法之一。它也被称为离子交换后电导率 (CACE)、酸电导率和交换后电导率。

离子“种类”或离子存在于样品流中,因为化合物在水中分解(溶解)。高工艺温度会加速这一过程。其他测量方法用于识别系统中的其他污染物。

这些离子可以带正电(阳离子)——包括钠、铜、铁、锰和氢——也可以带负电(阴离子),如氯化物和硫酸盐,它们特别令人担忧,因为它们是腐蚀源。阳离子电导率将带正电的离子从阳离子树脂柱中的工艺流中分离出来。

例如,在发电厂中,工程师希望识别可能因冷凝器管泄漏而存在的盐等污染物。盐会溶解并产生 NA+ 和 Cl-。阳离子树脂将捕获带正电的钠离子,取代带正电的氢离子,氢离子将与带负电的氯离子结合生成 HCL 并增加电导率测量值,从而表明存在污染物。

Cation conductivity is one of the best ways to monitor for contaminants within a steam or water sample. It is also referred to as Conductivity after Ion Exchange (CACE), Acid Conductivity and After Exchange Conductivity.

Ionic “species” or ions are present in a sample stream because compounds break down (dissolve) in water. High process temperatures accelerate this process. Other measurements are used to identify other contaminants in the system.

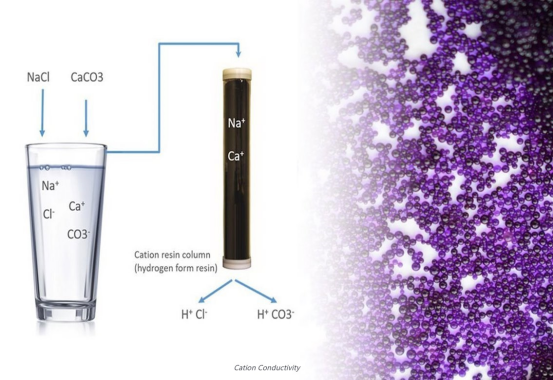

These ions can be positively charged (cations) – including sodium, copper, iron, manganese and hydrogen – and negatively charged (anions), like chlorides and sulfates which are of particular concern as they are sources of corrosion. Cation conductivity separates the positively charged ions from the process stream in a cation resin column.

As an example, in a power plant, we wish to identify contaminants like salts that might be present as a result of a condenser tube leak. The salt will dissolve and create NA+ and Cl-. The cation resin will capture the positively charged Sodium ions, displace a positively charged hydrogen ion which will bond with the negatively charged chloride ion creating HCL and increasing the conductivity measurement value thereby indicating a contaminant is present.

为什么阳离子电导率在公用设施中如此重要?

Why is cation conductivity significant in a utility plant?

阳离子电导率可防止污染物在工厂中引起更严重的问题。

例如,当氯化钠进入涡轮机并在涡轮叶片上形成沉积物,并且该涡轮机随后在没有任何干燥空气保护的情况下关闭时,氯化钠沉积物、空气中的氧气和水分的结合使氯离子变得具有高度腐蚀性并在涡轮叶片表面形成凹坑。随着时间的推移,这些凹坑可能导致灾难性的故障。

在高压锅炉(10 Mpag,1450 psig 及以上)中,氯化钠污染会导致锅炉管的严重腐蚀,从而导致水壁发生氢脆故障。阳离子电导率可以尽早发现这一问题,从而更大限度地提高工厂工艺中的清洁水并最大限度地减少停机时间。

Cation conductivity prevents contaminants from causing more significant issues in the plant.

For example, when sodium chloride enters a turbine and forms a deposit on the turbine blades and that turbine is later shut down without any dry-air protection, the combination of sodium chloride deposit, oxygen In the air and moisture allow the chloride ion to become highly corrosive and form pits on the turbine blade surfaces. Over time these pits can lead to catastrophic failures.

In high-pressure boilers (10 Mpag, 1450 psig and above) sodium chloride contamination can lead to aggressive corrosion of the boiler tubes leading to hydrogen embrittlement failures in the water walls. Cation conductivity can catch this problem early to maximize clean water in a plant’s processes and minimize downtime.

什么是阳离子树脂柱?

What are cation resin columns?

阳离子树脂柱通过使用带负电的塑料珠捕获溶液中的带正电的离子,将阳离子交换为阴离子。

带正电的阳离子与塑料珠上的功能组结合,取代释放的氢离子。释放的氢离子可以产生酸性溶液 - 这就是阳离子电导率有时被称为酸电导率或阳离子交换后电导率 (CACE) 的原因。阳离子树脂柱对污染物高度敏感,可以检测到低浓度的污染物。

非反应性塑料柱的长度与直径的比对于确保树脂的适当流动、停留时间和体积很重要。

大多数阳离子交换树脂都包含颜色指示剂,当树脂耗尽(无法交换离子)时,它会改变颜色,不同的树脂制造商使用不同的颜色指示剂染料,最常见的是深紫色或深红色,耗尽时分别变为浅棕色和浅红色。

颜色变化依次发生,直到所有树脂都耗尽。

当柱子中的所有树脂都变色时,树脂就无法再去除任何阳离子,阳离子会从柱子中流出,从而增加出口处的电导率。现在应该用新树脂或再生树脂替换旧树脂。

Cation resin columns exchange cations for anions by using negatively charged plastic beads to capture positively charged ions in a solution.

The positively charged cations bind to functional groups on the plastic beads, replacing a hydrogen ion which is released. The released hydrogen ions can create an acidic solution – that’s why cation conductivity is sometimes called acid conductivity or Conductivity after Cation Exchange (CACE). Cation resin columns are highly sensitive to contaminants and can detect low levels of them.

The length to diameter ratio of the non-reactive plastic column is important to ensure proper flow, residence time and volume of resin.

Most cation exchange resin includes a color indicator such that when the resin is exhausted (unable to exchange ions) it changes color, different resin manufacturers use different color indicator dyes most commonly deep purple or dark red, and change to light brown and light red, respectively, when exhausted.

The color change happens sequentially until all the resin is exhausted.

When all the resin in the column has changed color, the resin can no longer remove any cations and they can exit the column which increases the conductivity on the outlet. The resin should now be replaced with fresh resin or regenerated resin.

阳离子树脂柱可用于哪些应用?

What applications are cation resin columns used with?

阳离子树脂柱可用于多种应用,包括:

• 发现因发电厂腐蚀而产生的铁

• 检测矿物质和矿物盐/酸性污染物

• 检测钠,通常来自冷却系统泄漏,这可能会迅速损坏设备

• 识别可能将污染物引入工艺的泄漏

• 检测锅炉蒸汽中携带的化合物

Cation resin columns can be helpful in several applications, including:

• Spotting iron which is due to corrosion of the power plant

• Detecting minerals and mineral salts/acid contaminants

• Detecting sodium, typically from cooling system leaks which can damage equipment quickly

• Identifying leaks that can introduce contaminants to the process

• Detecting compounds carried over in the steam from the boiler

公用事业工厂在阳离子电导率方面经常面临哪些挑战?

What challenges do utility plants often face with cation conductivity?

有时工厂会使用设计不良或尺寸过大的阳离子交换筒,误以为这样可以延长使用寿命。然而,这可能会导致交换率不理想、树脂动力学不佳、浸出并导致测量不准确。

除了使用正确的离子交换柱、优质树脂以及在耗尽时更换或再生树脂外,样品温度也会对阳离子电导率测量产生不利影响。

例如,电导率对温度高度敏感,因此样品温度不能太高。通过使用高质量树脂、定期维护以及仔细控制样品流量和温度可以防止这些问题。不要仅仅依赖仪器的内置温度补偿,而是在工程师的操作条件下对其进行验证。

考虑使用二次取样冷却来消除温度偏差并提高测量稳定性。

Sometimes plants use poorly designed or oversized cation exchange cartridges with the misguided belief that they will extend service life. However, this can result in suboptimal exchange rates, poor resin kinetics, leaching and can lead to inaccurate measurements.

In addition to using the correct ion exchange column, good quality resin and replacing or regenerating the resin when exhausted, sample temperature can adversely affect cation conductivity measurements.

For example, conductivity is highly temperature-sensitive, so the sample temperature mustn’t be too hot. These issues are prevented by using high-quality resin, conducting regular maintenance, and carefully controlling the sample flow and temperature. Don’t just rely on an instrument’s built-in temperature compensation, validate it in your operating conditions.

Consider using secondary sample cooling to remove temperature bias and improve measurement stability.

公用事业工厂如何确保阳离子电导率计划成功?

How can utility plants ensure a successful cation conductivity program?

确保用户使用适当的阳离子树脂柱尺寸来提供所需的运行时间,并且测量传感器在与电导率传感器兼容的流速下是准确的,通常约为每分钟 100 到 200 cc。

此外,确保用户了解 EPRI、IAPWS 和 ASTM 的最新指南和最佳实践。如果需要,可以聘请专家合作伙伴来确保测量准确可靠。

将用户的分析系统与 EPRI 和 IAPWS 指导进行基准测试,以确定工厂类型、化学和操作参数的最低核心仪器。考虑使用智能化学警报增强系统,以提高对测量的信心。

Ensure you utilize the appropriate cation resin column size to deliver the runtime you require and that your measurement sensor is accurate at flow rates compatible with conductivity sensors, usually about 100 to 200 cc per minute.

Additionally, assure you are up-to-date on the latest guidelines and best practices from EPRI, IAPWS and ASTM. If needed, you can pull in an expert partner to ensure your measurements are accurate and dependable.

Benchmark your analytic system to EPRI and IAPWS guidance on minimum core instrumentation for your plant type, chemistry and operating parameters. Consider augmenting the system with Smart Chemistry Alarms for improved confidence in measurements.

声明:

- 文章转载自SENTRY,由爱泽工业翻译,如有侵权,请联系删除!

- 如有偏颇,欢迎指正!

沪公网安备31011002006738号

沪公网安备31011002006738号