流量仪表的检验和校准

检查/校准

Inspection/calibration

检验校准使用通用标准流程处理,如目视检查、拆卸/检查、零件更换/维修、清洁、流量校正/校准等。校准方法将根据日本工业标准(使用浮子面积流量计的测量方法)进行选择。 (出具检验结果)

检验项目会根据所使用的工艺、连续/间歇操作、流体状况、安装位置(室内/室外)、流量计类型等而有所不同,除特殊情况外,检查和校准通用标准项目。主要管理项目包括目视检查、修理、拆卸清洗、零件更换、脉动和流量快速变化、修正系数计算等。将根据日本工业标准(使用浮子面积流量计测量流量的方法)选择校准方法,具体取决于要测量的流体和测量系统的类型(校准方法将在检查报告中注明) 。

Handle general standard processes such as visual inspection, disassembly/inspection, parts replacement/repair, cleaning, flow correction/calibration, etc. The calibration method will be selected based on the Japanese Industrial Standards (measurement method using a float area flow meter). (Issuance of inspection results)

Items to be inspected will vary depending on the process used, continuous/intermittent operation, fluid condition, installation location (indoor/outdoor), type of flowmeter, etc. , except in the case of special conditions, will inspect and calibrate general standard items. The main management items include visual inspection, repair, disassembly and cleaning, parts replacement, pulsation and rapid flow changes, and calculation of correction coefficients. The calibration method will be selected based on the Japanese Industrial Standards (Method of measuring flow rate using a float area flowmeter), depending on the fluid to be measured and the type of measurement system (the calibration method will be stated in the inspection report).

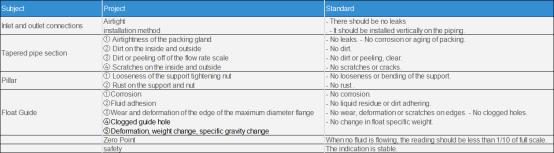

检验管理项目

Inspection management items

• 锥形管上的污垢

• 浮子的运动

• 流体密封泄漏

• 与流体接触部件的腐蚀

• 浮体腐蚀/变形

• 温度、压力等测量条件的变化

• Dirt on the tapered pipe

• movement of float

• Leakage from fluid seal

• Corrosion of parts in contact with fluid

• Corrosion/deformation of float

• Changes in measurement conditions such as temperature and pressure

检验管理项目

Inspection management items

• 请选择震动小的地方安装。另外,请选择易于更换和清洁浮子及其他部件的安装位置。

• 安装时应使锥形管的中心轴垂直。如果锥形管的中心轴相对于垂直线倾斜,精度和灵敏度会下降,因此请注意上升管的垂直度和安装面的水平度。

• 提供旁通管路,这样即使流量计因维修或保养而被拆下,操作也不会受到影响。

• 固定管道,使管道系统中产生的应力不会传递到流量计。

• 避免在入口或出口之前快速膨胀或收敛,因为这可能会导致浮子变得不稳定。

• 缓慢地打开和关闭阀门,以避免流量计突然受到冲击。 (FLO-PL18型/FLO-L68型)

• 小心不要让锥形管(硬玻璃)遭受突然的温度变化。

• 请注意不要使用被异物污染的液体,否则可能会导致故障。

• 为防止液体结冰造成损坏,冬季停止运行时应排空液体或保温。

• 锥形管上有污垢

• Please choose a location with little vibration for installation. Also, please select an installation location where it is easy to replace and clean the float and other parts.

• Install so that the center axis of the tapered pipe is vertical. If the central axis of the tapered pipe is tilted with respect to the vertical line, accuracy and sensitivity will decrease, so please be careful about the verticality of the rising pipe and the horizontality of the mounting surface.

• Provide a bypass line so that even if the flowmeter is removed for repairs or maintenance, operation will not be affected.

• Fix the piping so that the stress generated in the piping system is not transmitted to the flowmeter.

• Avoid rapid expansion or convergence immediately before the inlet or outlet, as this may cause the float to become unstable.

• Open and close the valve slowly to avoid sudden shock to the flow meter. (FLO-PL18 type/FLO-L68 type)

• Be careful not to subject the tapered tube (hard glass) to sudden temperature changes.

• Be careful not to use fluids that are contaminated with foreign substances, as this may cause malfunctions.

• To prevent damage due to fluid freezing, drain the fluid or keep it warm when suspending operation in winter.

• Dirt on the tapered pipe

面积流量计原理

Principle of area flow meter

面积流量计的流量测量部分有一根垂直安装在管道上的锥形管和一个在锥形管之间上下移动的浮子(可动部分),流体从锥形管的底部进入并向上流出。

当流体开始流动时,浮子前后会产生压力差,浮子上下移动,因此无论流量如何变化,此时在浮子和浮子之间都会产生压力差。锥形管的环形面积与流量成正比关系。随着流量增大,浮子向上运动,环形面积增大,产生向上的力(前后压差、流体产生的浮力、浮子表面摩擦力等)和向下的力(浮子的重量) )可以保持静止,直接或间接检测位置,测量瞬时流量值。

The flow rate measurement part of an area flow meter has a tapered pipe installed vertically on the pipe and a float (movable part) that moves up and down between the tapers, and the fluid enters from the bottom of the tapered pipe and flows out upward.

When fluid begins to flow, a pressure difference is created in front and behind the float, and the float moves up and down so that this pressure difference remains constant regardless of changes in flow rate. At this time, it is created between the float and the tapered pipe. There is a proportional relationship between the annular area and flow rate. As the flow rate increases, the float moves upward and the annular area increases, and the upward force (differential pressure before and after, buoyant force due to the fluid, float surface friction force, etc.) and downward force (weight of the float) are balanced. It can stand still at a position, detect the position directly or indirectly, and measure the instantaneous flow value.

声明:

- 文章转载自RYUKI,由爱泽工业翻译,如有侵权,请联系删除!

- 如有偏颇,欢迎指正!

下一篇:有关RFID(射频识别)介绍

沪公网安备31011002006738号

沪公网安备31011002006738号