对本质安全(本安)设计的常见误解(中英文)

本质安全——辨别真相与谬误

Intrinsic Safety – separating fact from fiction

在工业应用中实现本质安全 (IS,以下简称本安) 是保护人员、设备和产品免受风险的关键所在。但大众对本安及其实现方式究竟了解多少呢?本文EATON MTL 本安产品线经理 Roger Highton 将揭开本质安全的真相。

几乎所有行业都普遍存在潜在易燃物质。无论是海上石油钻井平台、化工厂、面粉厂、水处理厂还是汽车喷漆车间,只要易燃气体、粉尘或蒸汽的浓度达到一定程度,就存在火灾或爆炸的风险。本安 (IS) 是一种电气设计方法,它通过确保传递到危险区域的能量远低于引发爆炸所需的能量来防止爆炸的发生。这种能量可以以电火花或高温表面的形式存在。

本安的主要优势在于,它为危险区域(适用于功率有限的设备)的所有问题提供了解决方案,并且是唯一符合此标准的技术。此外,本质安全技术已被普遍接受,并纳入所有地方法规,包括ATEX和OSHA。尽管如此,关于本安的常见误解仍然存在。以下是最想澄清的五个误解。

Achieving intrinsic safety (IS) in industrial applications is an essential part of protecting people, plant and product from risk. But how well do we understand IS and how to achieve it? Roger Highton, MTL Product Line Manager for intrinsic safety at Eaton, separates the facts from the fiction.

The presence of potentially flammable substances is a common occurrence in virtually any industry. Whether the environment is an offshore oil rig, a chemical plant, a flour mill, a water treatment works or a vehicle paint-shop, if flammable gases, dusts or vapours accumulate in sufficient concentration there is a risk of fire or explosion. Intrinsic safety (IS) is an electrical design approach that prevents explosions from occurring by ensuring that the energy transferred to a hazardous area is well below the energy required to initiate an explosion. This energy can take the form of an electrical spark, or a hot surface.

The major advantage of intrinsic safety is that it provides a solution to all the problems of hazardous areas (for equipment requiring limited power) and is the only technique which meets this criterion. In addition, the IS technique is universally accepted and is incorporated under all local legislation: including ATEX and OSHA. Despite this, common misunderstandings about IS persist. Here are the five we’d most like to debunk.

误区一:添加本安接口就能使设备本安

Myth #1 – Adding an IS interface will make my equipment intrinsically safe

这是一个常见的误区,但却可能造成危险。增加本安接口(隔离器或屏障)并不能使任何设备成为本安设备。只有安装专门设计用于满足本安要求的设备以及合适的本安接口,才能真正降低爆炸风险。当本安设备通过线路互连时,每台设备的安全性都会受到电路中其他设备性能的影响。本安技术依赖于系统的正确设计,而本安本身就是一个系统概念。其他防爆方法也在一定程度上依赖于系统概念,但本安是其根本要求。

This is a common myth, but a potentially dangerous one. Adding an IS interface (isolator or barrier) does not make any equipment intrinsically safe. Mitigation of explosion risk can only be achieved by installing equipment that has been specifically designed to meet IS requirements along with a suitable IS interface. Where intrinsically safe equipment is interconnected by wiring, the safety of each piece of equipment is affected by the performance of the other pieces of apparatus in the circuit. The IS technique relies on the system being correctly designed and intrinsic safety becomes a system concept. Other methods of explosion protection are also dependent on the system concept to some extent, but it is a fundamental requirement of intrinsic safety.

误区二:IS接口的安全描述与IS设备兼容,设计完成

Myth #2 – The safety description of the IS interface is compatible with the IS device, design complete

仅仅通过检查IS接口的电压,电流和功率输出(Uo、Io和Po)是否小于IS设备的电压,电流和功率输入(Ui,Ii和Pi)来评估安全描述的兼容性,并不能保证为IS环境选择的组件能够有效运行。第一步是确保设备完全符合相关安全要求。第二步则着眼于实际应用。设备能否正常工作?对于接口而言,这需要仔细检查电压和电流等运行参数。

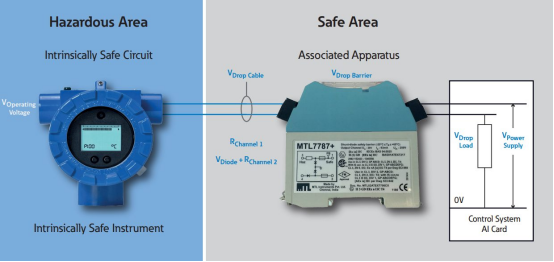

为了说明这一点,在考虑一个使用两线制环路供电变送器的模拟输入应用(见图1)。该变送器具有最低工作电压,通常为10.5V。IS接口必须能够在扣除电缆压降后提供该电压。

Assessing the safety description compatibility by checking that the voltage, current and power outputs (Uo, Io and Po) of the IS interface is less than the voltage, current and power inputs (Ui, Ii and Pi) of the IS device alone does not guarantee that components selected for IS environments will function effectively. The first step is to ensure that the device is fully compliant and meets the relevant safety requirements. The second step is all about the practicalities. Will the device function properly? For interfaces, this requires careful checking of operational parameters such as voltage and current.

To illustrate this point, let us consider an application for an analogue input with a 2-wire loop powered transmitter (see Figure 1). This will have a minimum operational voltage, typically 10.5V. The IS interface must be able to supply this voltage after subtracting the voltage drop in the cabling.

图 1 – 此图显示了一个带有2线环路供电发射器的模拟输入

Figure 1 – This illustration shows an analogue input with a 2-wire loop powered transmitter

考虑使用无源屏障来解决这个问题,并利用欧姆定律评估屏障两个通道上的电压降以及典型的 250Ω 安全区域负载上的电压降。计算如下:

VDrop Barrier = Imax x (RChannel 1 + RChannel 2) + VDiode Drop = 20mA/1000 x (333Ω + 21Ω) + 0.9V = 7.98 V

VDrop Load Resistor = Imax x RLoad = 20mA/1000 x 250Ω = 5V

VDrop Cable = VPower Supply – VDrop Barrier – VDrop Load – VOperating Voltage = 24V – 7.98V – 5V – 10.5V = 0.52V

RCable = VDrop Cable/ Imax = 0.52V /20mA/1000 = 26Ω

Cable length = RCable/ROne km Cable = 26Ω/50Ω/km = 0.52km

由此可见,电缆电阻可达 26Ω,在 50Ω/km 的电缆电阻下,可支持 520m 的电缆长度。然而,电源电压哪怕只有很小的降幅(0.6V)也会导致回路失效。

隔离栅和有源隔离栅可提供最低电压保证,对于此应用中使用的典型隔离器(例如 MTL5541),在 20mA 电流下最低电压为 16.5V。因此,在 16.5 - 10.5 = 6V 的可用电缆压降下,此方案提供了更大的运行裕度。

Let’s consider a passive barrier for this application, assessing the voltage drop across both channels of the barrier plus the voltage drop across the typical 250Ω safe area load using Ohm’s Law. The calculation is as follows:

VDrop Barrier = Imax x (RChannel 1 + RChannel 2) + VDiode Drop = 20mA/1000 x (333Ω + 21Ω) + 0.9V = 7.98 V

VDrop Load Resistor = Imax x RLoad = 20mA/1000 x 250Ω = 5V

VDrop Cable = VPower Supply – VDrop Barrier – VDrop Load – VOperating Voltage = 24V – 7.98V – 5V – 10.5V = 0.52V

RCable = VDrop Cable/ Imax = 0.52V /20mA/1000 = 26Ω

Cable length = RCable/ROne km Cable = 26Ω/50Ω/km = 0.52km

As a result, we can see that the cable resistance could be 26Ω, which – with a cable resistance of 50Ω/km – could support 520m of cable. However, just a small drop (0.6V) in the power supply voltage would cause failure of the loop.

Isolating barriers and active barriers provide a guaranteed minimum voltage which, for a typical isolator used in this application (such as Eaton’s MTL5541), is a minimum of 16.5V at 20mA. So, with an available voltage drop for cabling of 16.5-10.5 = 6V, this solution provides a much greater operational margin.

误区三:齐纳二极管安全栅和隔离器可以互换

Myth #3 – Zener barriers and isolators are interchangeable

本安型设备用户广泛采用的IS接口主要有两种:IS齐纳二极管安全栅和IS隔离栅。最终用户通常会选择使用其中一种,因此建议他们继续使用同一种接口类型。这两种接口的安装和维护要求截然不同,因此了解它们至关重要。

大多数IS齐纳二极管安全栅结构简单,用途广泛,采用回路供电,需要严格控制的电源,在危险区域和安全区域的连接中,可用电压都有限。它们需要定期测试安全接地,因为这是该技术安全性的基本要求。IS隔离器结构更复杂,平均故障间隔时间(MTTF)更短。它们针对特定应用而设计,可与多种电源配合使用,在危险区域和安全区域的连接中均可提供更高的电压,并简化了日常检查要求。

There are two types of IS interfaces widely adopted by users of intrinsic safety: IS Zener barriers and IS isolating barriers. An end user site will usually have elected to use one or the other, so it is recommended that they continue to use the same interface type. These interfaces have very different installation and maintenance requirements, so it is important to understand them.

Most IS Zener barriers are simple, versatile, loop powered interfaces that require a tightly controlled power source, with limited voltage available in both hazardous and safe area connections. They require a safety earth that is regularly tested as it is a fundamental requirement of the safety of this technique. IS isolators are more complex with a shorter Mean Time To Failure (MTTF). They are application specific, can be used with a wide range of power supplies, can provide higher voltage in both hazardous and safe area connections, and simplify regular inspection requirements.

误区四:只要设备通过了本安认证,使用什么电缆都无所谓

Myth #4 – It doesn’t matter what cabling you use if the equipment is certified IS

由于电缆具有电感和电容,因而具有储能能力,它们会影响系统安全。因此,系统设计会对这些参数的值进行限制;但很少会对可用电缆本身做出严格的限制。

由于系统分析中已考虑了电缆故障,因此系统标准并未对具体安装中使用的电缆类型做出详细规定。电缆的选择取决于系统可靠运行的需求。当本安系统采用多芯电缆时,则存在一些特殊要求。这些要求决定了需要考虑哪些额外的故障。

本安无需使用铠装或导管对电缆进行机械保护,因此可以使用传统的仪表电缆,从而降低成本。电缆参数检查也很简单,只需确保电缆和现场设备的电容和电感小于设备所在气体组本安接口允许的电容和电感值即可。通常的做法是计算特定安装允许的最大电缆长度,并在设计电缆敷设时确保不超过该长度。

Because cables have inductance and capacitance, and hence energy storage capabilities, they can affect system safety. Consequently, the system design imposes restrictions on the value for each of these parameters: but only rarely is there a serious limitation placed on the available cable.

As cable faults are taken into account during the system analysis, the type of cable in individual installations is not closely specified in the system standard. The choice is therefore determined by the need for reliable system operation. Where intrinsically safe systems are combined in a multi-core, then there are special requirements. These determine which additional faults have to be considered.

Intrinsic safety does not require mechanical protection of the cable with armour or conduit, permitting the use of conventional instrumentation cables and thus reducing costs. The cable parameter checks are straightforward, simply requiring that the capacitance and inductance of the cable and field devices is less than the capacitance and inductance allowed for the IS interface for the Gas Group in which the equipment is installed. Usual practice is to calculate the maximum cable length allowed for a particular installation, ensuring this is not exceeded when designing the cable runs.

误区五:在Ex ic标准下,本安系统在2区不如在1区严格

Myth #5 – Under Ex ic, the IS system rules are not as strict in Zone 2 as they are for Zone 1

这种误区源于对Ex标识的误解。本安采用三个防护等级:“ia”、“ib”和“ic”,分别用于平衡爆炸性气体环境出现的可能性和可点燃情况发生的可能性。这些防护等级的使用确保了每个风险等级都有相应的设备可用(通常”ia”用于0区,“ib”用于1区,“ic”用于2区)。2区标识表明爆炸风险不常见。

在Ex ic被纳入本安标准之前,设计人员只能在安装指导有限的情况下评估不同接线方案的风险。现在,对于如何在2区指定区域安装和维护本安设备,已经有了明确的指导方针。例如,要求将露的 IS 导体与非 IS 电路隔离至少 50 毫米,这使得配线盘的布局要求变得明确。

This myth arises from a misinterpretation of the Ex designations. Intrinsic safety utilises three levels of protection, ‘ia’, ‘ib’ and ‘ic’ which balance the probability of an explosive atmosphere being present against the probability of an ignition-capable situation occurring. The use of these levels of protection ensures that equipment suitable for each level of risk is available (normally ‘ia’ is used in Zone 0, ‘ib’ in Zone 1 and ‘ic’ in Zone 2). The Zone 2 designation indicates that the risk of an explosive is infrequent.

Until Ex ic was incorporated in the intrinsically safe standards, the designer had to assess the risk of different wiring options with minimal guidelines on installation. There are now clear guidelines on how intrinsically safe equipment should be installed and maintained in Zone 2 designated areas. One example is a requirement for segregation of an exposed IS conductor of at least 50mm from a non IS circuit, which makes the requirements for layout of a marshalling panel clear.

结语

Final word

信息系统设计者必须对设计的充分性以及在危险区域使用该系统所带来的安全隐患承担责任。因此,设计者必须具备相应的知识和培训水平,并应认识到正确分析的重要性。

简单系统的分析相对容易,任何合格的专业工程师都可以完成。从信誉良好的制造商(例如 Eaton MTL)采购信息系统设备可以提供进一步的保障和专业知识。对于更复杂的系统——例如使用非线性电源和线性电源组合的系统,此类系统需要更丰富的经验——最好联系“认可的认证机构”进行系统分析。

The IS system designer must accept responsibility for the adequacy of the design and the safety implications of the use of the system in association with hazardous areas. The designer must therefore have an appropriate level of knowledge and training and should recognise the importance of getting the analysis right.

The analysis of simple systems is relatively easy and can be done by any competent professional engineer. Sourcing IS equipment from reputable manufacturers such as Eaton MTL may provide further reassurance and expertise. For more complex systems – such as those using a combination of non-linear and linear sources of power where a greater degree of experience is required – it may be desirable to approach an ‘approved certification body’ to provide an analysis for such a system.

声明:

-文章转载自EATON,由爱泽工业翻译,如有侵权,请联系删除!

-如有偏颇,欢迎指正

沪公网安备31011002006738号

沪公网安备31011002006738号