气动执行器的类型和应用(中英文)

本文主要介绍气动执行器。仔细研究最常见的气动执行器——弹簧/膜片线性气动执行器的操作和应用。

In this article, we’re going to talk about pneumatic actuators. We’ll look closely at the operation and application of the most common pneumatic actuator, the spring/diaphragm linear pneumatic actuator.

首先了解一下执行器。什么是执行器?简单地说,执行器是一种使物体移动或运行的装置。

First of all, let’s look at Actuators in general. What is an Actuator? Simply stated, an actuator is a device that makes something move or operate.

根据能源分类的执行器

Types of actuators by their energy source

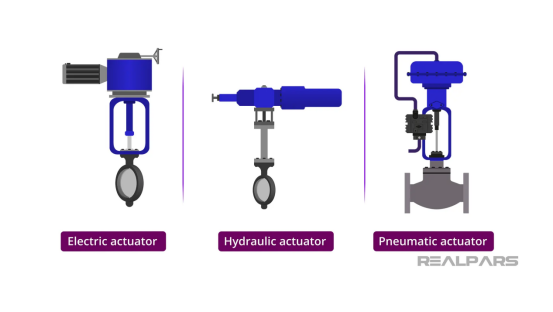

根据其能源的不同,工业中使用的执行器分为三种典型类型。

工业中典型的执行器包括:

– 电动

– 液压

– 气动

There are three typical types of actuators used in industry as defined by their energy source.

The typical actuators in the industry include:

– Electric

– Hydraulic

– Pneumatic

回归本文重点——气动执行器。气动执行器将压缩空气的能量转化为运动。

Ok… Let’s move on to the focus of our article, the pneumatic actuator. A pneumatic actuator converts energy in the form of compressed air into movement.

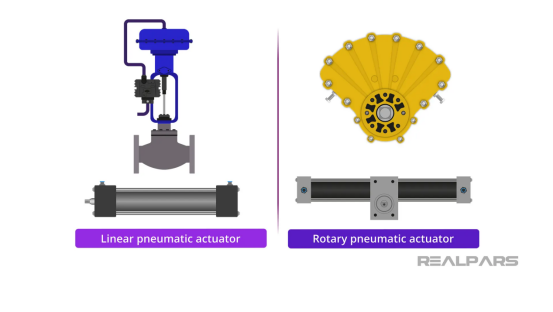

根据运动方式分类的执行器

Types of actuators by their motion

气动执行器根据其运动类型进行分类。气动执行器分为线性执行器和旋转执行器。

Pneumatic actuators are categorized by their type of motion. They are either Linear or Rotary.

线性气动执行器可以直线移动物体。例如,杆通过气动能源以线性运动进出气缸。

A linear pneumatic actuator can move something in a straight line. For example, a rod is moved in and out of a cylinder in a linear motion by a pneumatic energy source.

旋转气动执行器可以使物体以圆周运动移动。例如,齿条齿轮传动系统中的杆用于产生旋转运动。

A rotary pneumatic actuator can make something move in a circular motion. For example, a rod in a rack and pinion drive system is used to produce rotary motion.

以下是一些旋转和线性气动执行器如何操作的例子,每种执行器都有许多不同的类型。

Let’s look at some examples of how Rotary and Linear pneumatic actuators are operated as there are many different types of each.

1) 旋转气动执行器/Rotary pneumatic actuator

在旋转气动执行器类别中,叶片式和齿条齿轮式非常常见。

In the Rotary pneumatic actuator category, the Vane style and the Rack and Pinion style are very common.

1-1) 叶片执行器/Vane Actuator

叶片执行器有一个圆柱形腔室,其中可移动的叶片安装在轴上。施加在叶片一侧的压力气动空气使其在冲程内旋转。

Vane Actuators have a cylindrical chamber in which a movable vane is mounted on a shaft. Pneumatic air under pressure applied on one side of the vane causes it to rotate through its stroke.

1-2) 齿轮齿条/ Rack and pinion

齿轮齿条执行器使用连接到齿条齿轮的活塞。当施加气动压力时,活塞和齿条线性移动,从而旋转小齿轮和驱动轴。

Rack and Pinion actuators use a piston attached to rack gear. When pneumatic pressure is applied, the piston and rack move linearly rotating the pinion gear and driveshaft.

2) 线性气动执行器/Linear pneumatic actuator

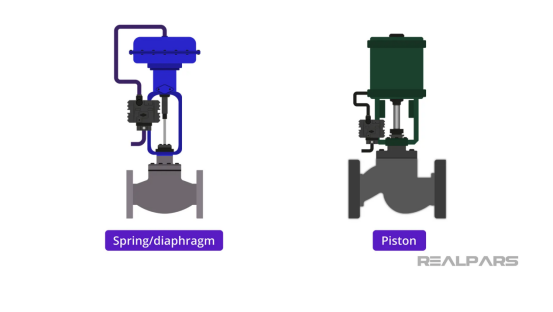

在线性气动执行器类别中,弹簧/膜片式和活塞式非常常见。

In the Linear pneumatic actuator category, the spring/diaphragm style and the piston style are very common.

2-1) 活塞/ Piston

活塞式气动执行器利用气缸内的活塞。活塞的运动是由施加气动压力引起的,从而使活塞向上移动。

去除气动压力会导致活塞在弹簧压力的作用下向下移动。这种运动称为空气缩回。

也可以通过重新排列弹簧、活塞和气动供应来实现空气伸展运动。

The piston-style pneumatic actuator utilizes a piston inside a cylinder. The movement of the piston is caused by applying pneumatic pressure thereby moving the piston upwards.

Removing the pneumatic pressure causes the piston to move downward due to the pressure of the spring. This motion is referred to as Air-to-Retract.

An Air-to-Extend motion can be also be achieved by rearranging the spring, piston, and pneumatic supply.

2-2) 弹簧/隔膜/Spring/diaphragm

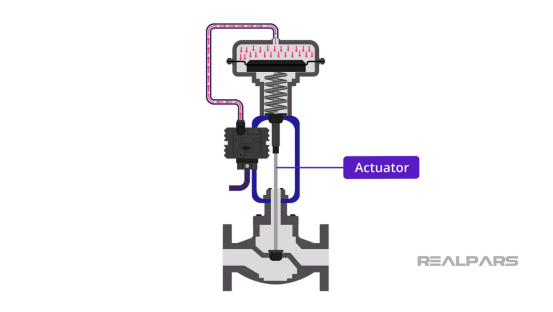

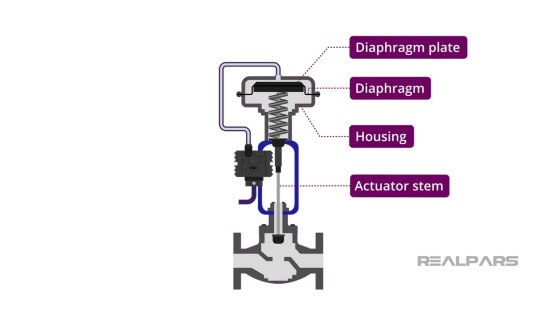

弹簧/隔膜气动执行器是用于操作工业过程控制阀的常见执行器。

弹簧/隔膜气动执行器由连接到执行器杆的隔膜和板组成。柔性隔膜封装在耐压外壳中。

The spring/diaphragm pneumatic actuator is probably the most common actuator used to operate industrial process control valves.

The spring/diaphragm pneumatic actuator consists of a diaphragm and plate that are connected to an actuator stem. A flexible diaphragm is enclosed in pressure-tight housing.

气动压力进入该壳体,对隔膜施加压力。随着隔膜上的气压增加,施加在弹簧上的力也随之增加,导致执行器杆移动。

降低气动压力将导致弹簧缩回隔膜。

执行器杆将阀门移入或移出阀体。

在气开操作条件下,弹簧迫使阀门关闭。

隔膜上的气压产生克服弹簧力并打开阀门的力。

通过重新安排弹簧气动供应,这种类型的执行器可以在气压丢失时自动打开或关闭。

Pneumatic pressure enters this housing applying pressure to the diaphragm. As the air pressure increases to the diaphragm the force exerted against the spring increases causing the actuator stem to move.

Reducing the pneumatic pressure will cause the spring to retract the diaphragm.

The actuator stem will move a valve in or out of a valve body.

In an air-to-open operating condition, the spring forces the valve closed.

The air pressure on the diaphragm creates a force that overcomes the force of the spring and opens the valve.

By rearranging the spring pneumatic supply, this type of actuator can fail-open or fail-closed when air pressure is lost.

气动执行器的运行

Pneumatic actuator in action

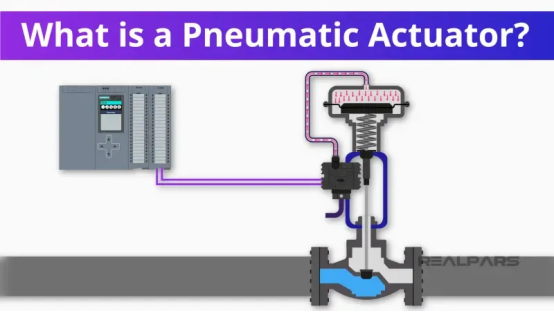

连接到流量控制阀的典型弹簧/隔膜气动执行器的运行情况。

PLC 模拟输出卡产生 4 至 20 mA 电流,使阀门从全开到全关。

Let’s look at a typical spring/diaphragm pneumatic actuator connected to a flow control valve in action!

The PLC analog output card produces a 4 to 20 mA current to move the valve from fully open to fully closed.

称为电流压力传感器或 I/P 的信号调节器会将 4 至 20 mA 转换为 3 至 15 psi。

A signal conditioner called a current-to-pressure transducer or I/P will change the 4 to 20 mA into 3 to 15 psi.

总结

Summary

– 执行器是一种使物体移动或运行的装置。

– 执行器接收能量源并使用它来移动物体。

– 三种典型的执行器能量源是气动、电动和液压。

– 气动执行器将压缩空气形式的能量转化为运动。

– 气动执行器可以以线性运动或旋转运动移动物体。

– 线性气动执行器包括弹簧/隔膜式和活塞式。

– 旋转气动执行器包括旋转叶片式和齿条齿轮式。

– An actuator is a device that makes something move or operate.

– An actuator receives a source of energy and uses it to move something.

– The three typical actuator energy sources are Pneumatic, Electric, and Hydraulic.

– A pneumatic actuator converts energy in the form of compressed air into motion.

– A pneumatic actuator can move something in a linear motion or a rotary motion.

– Linear pneumatic actuators include the spring/diaphragm style and the piston style.

– Rotary pneumatic actuators include the rotary vane style and the Rack and Pinion style.

声明:

- 文章转载自REALPARS,由爱泽工业翻译,如有侵权,请联系删除!

- 如有偏颇,欢迎指正!

下一篇:关于KCs认证介绍(中英文)

沪公网安备31011002006738号

沪公网安备31011002006738号