AMAC品牌介绍

自 20 世纪 70 年代末以来,AMAC Corrosion 一直为采矿、建筑、制造、石化、管道、造船厂和政府机构等众多行业提供创新的阴极保护系统。

Since the late 1970's, AMAC Corrosion has been providing innovative cathodic protection systems to a wide range of industries including mining, construction, manufacturing, petrochemical, pipelines, shipyards and government bodies.

AMAC Corrosion 通过为客户提供高品质的产品、出色的支持和友好的销售与服务,保持了其在阴极保护行业中的地位和声誉。AMAC Corrosion 的优势在于其在全球腐蚀保护挑战过程中积累的丰富经验。AMAC Corrosion 拥有解决问题的优良传统,并以其提供实用且经济高效的解决方案的能力而自豪。

AMAC Corrosion’s capability and reputation as a leader in the cathodic protection industry has been sustained by providing customers with high quality product, excellent support, and friendly sales and service. AMAC Corrosion’s strength is in the wide range of experience accumulated in successfully completing corrosion protection challenges throughout the world. AMAC Corrosion has a strong tradition of problem solving and takes pride in its ability to provide practical and cost effective solutions.

腐蚀与阴极保护

CORROSION AND CATHODIC PROTECTION

金属腐蚀

Metallic Corrosion

金属腐蚀是金属和合金通过电化学反应而变质或破坏的过程。所有金属都有恢复到稳定状态的趋势。主动寻求稳定状态的金属电位较低,最容易腐蚀(阳极)。被动寻求稳定状态的材料电位较高,不易腐蚀(阴极)。

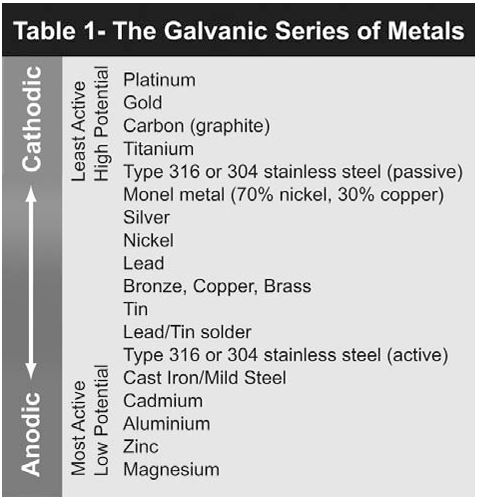

金属可根据其溶解倾向进行分类。下表(金属的电位系列)是根据不同金属相对于参比电极测量的电位编制的。

Metallic Corrosion is the deterioration or destruction of metals and alloys through electrochemical reactions. All metals have a tendency to return to a stable condition. Those metals that actively seek a stable condition have lower potentials and are most prone to corrosion (anodic). Those materials that passively seek a stable condition have higher potentials and are less prone to corrosion (cathodic).

Metals can be classified according to their tendency to dissolve. The following table (The Galvanic Series of Metals) is compiled according to the potentials of different metals measured against a reference electrode.

阴极保护

Cathodic Protection

所有阴极保护系统的目的都是通过促进电子从活性阳极流向被动阴极来降低阴极的腐蚀速度。

阳极提供电流,在牺牲阳极的情况下,随着离子溶解到电解质中,阳极会逐渐腐蚀。在外加电流系统的情况下,电位差是通过低压直流电流产生的。

The aim of all cathodic protection systems is to reduce the rate of corrosion of the cathode by promoting the flow of electrons from the active anode to the passive cathode.

The anode supplies the current, which in the case of a sacrificial anode, causes the anode to gradually corrode as the ions dissolve into the electrolyte. In the case of impressed current systems, the potential difference is created via a low voltage DC current.

为何选择 AMAC 阳极?

WHY CHOOSE AMAC ANODES?

合金成分

Alloy Composition

为了提供更佳的防腐蚀保护,牺牲阳极必须符合相关规定的化学规格。如果阳极不符合这些规格,它们可能只提供有限的保护,没有保护,或者更糟的是,实际上会导致腐蚀。

AMAC Corrosion 的实验室会根据 NATA 批准的主样品对每批阳极材料中的至少一个样品进行光谱测试。每批的每个样品都会储存至阳极的设计寿命。此过程可确保每个 AMAC 阳极都以最佳容量运行,从而提供更有效的保护。

To provide optimum protection from corrosion, sacrificial anodes must meet the chemical specifications identified in Australian and International standards. If anodes do not meet these specifications, they may offer limited protection, no protection, or worse still, actually cause corrosion.

AMAC Corrosion’s laboratory spectrographically test at least one sample from every batch of anode material against a NATA approved master sample. Every sample from each batch is stored for the design life of the anode. This process ensures that every AMAC anode functions at its optimum capacity, and therefore offers the most effective protection..

质量保证

Quality Assurance

为生产出始终如一的高质量产品,AMAC Corrosion 已通过劳氏质量认证中心的 ISO9001 认证。AMAC Corrosion 每 6 个月对关键流程进行一次密集的独立审核,每 3 年进行一次证书更新审核。

AMAC 至少在 2012 年之前就获得 ISO9001 认证

AMAC 腐蚀管理系统涵盖生产过程的每个阶段——从设计、制造、一直到交付。AMAC 腐蚀管理系统的主要目标不断改进。这是通过审查和改进生产高质量产品所需的所有流程来实现的。

To ensure the production of uniformly high quality products, AMAC Corrosion is certified to the requirements of ISO9001 by Lloyds Register Quality Assurance. AMAC Corrosion undergo intensive independent audits of critical processes every 6 months, with a certificate renewal audit every 3 years.

AMAC is ISO9001 accredited until at least 2012

The AMAC Corrosion Management System covers every stage of the production process – from design, to manufacture, right through to delivery. The key objective of the AMAC Corrosion management system is to improve continually. This is achieved by reviewing and refining all processes critical to producing high quality products.

声明:

- 文章转载自AMAC ,如有侵权,请联系删除!

- 如有偏颇,欢迎指正!

沪公网安备31011002006738号

沪公网安备31011002006738号