美国WHITTET-HIGGINS锁紧螺母丨垫圈丨轴环

WHITTET-HIGGINS设计和制造工业固定装置。WHITT-HIGGINS的产品用于轴承、动力传输和其他机械及设备组件的商业和精密保持装置,包括机械锁、有效扭矩、带锁紧垫圈的锁紧螺母、适配器套件、普通轴环和螺纹轴环。

WHITTET-HIGGINS产品线介绍

机械锁

Whittet-Higgins 拥有广泛的机械锁保持装置系列,包括Bearlok、Shoelok和Clampnut。有多种材料的公制和英制尺寸可供选择。BL、CNB、NSH和TLN系列中的精密轴承螺纹按照National Standard Class 3制造。BLM、CNM、NSHM和TLM系列中的精密ISO公制螺纹按照4H级制造。 Clampnut系列CNC、CNF、CNS、SNC、SNF 和 SNS中的统一螺纹按照2B类制造。

Mechanical Lock

Whittet-Higgins has an extensive line of mechanical lock retaining devices, including the Bearlok, Shoelok, and Clampnut. Avalailable in both metric and inch sizes in a variety of materials. Precision bearing threads in Series BL, CNB, NSH, and TLN are manufactured to National Standard Class 3. Precision ISO metric threads in Series BLM, CNM, NSHM, and TLM are manufactured to Class 4H. Unified threads in Clampnut series CNC, CNF, CNS, SNC, SNF, and SNS are manufactured to Class 2B.

有效扭矩

BH、BHL、BHM、BHS和BHT系列的精密轴承螺纹按照National Standard Class 3制造。BM、BML、BMM、BMS和BMT系列的精密ISO公制螺纹按照4H级制造。BHI系列中的统一螺纹按照3B级制造。

Prevailing Torque

Precision bearing threads in Series BH, BHL, BHM, BHS, and BHT are manufactured to National Standard Class 3. Precision ISO metric threads in Series BM, BML, BMM, BMS, and BMT are manufactured to Class 4H. Unified threads in Series BHI are manufactured to Class 3B.

精密系列

PN、PL 和 PT 系列的精密轴承螺纹按照National Standard Class 3制造。

Precision Series

Precision bearing threads in Series PN, PL, and PT are manufactured to National Standard Class 3.

SAE/AFBMA/ABMA/ANSI/ISO/MIL的螺母/垫圈

KM系列中的精密ISO公制螺纹按照4H级制造。MS-172236系列中的精密轴承螺纹按照MIL-S-8879制造。MS-19068、N/AN、N-000和NE系列中的精密轴承螺纹按照国家标准3级制造。

Nuts/Washers of SAE/AFBMA/ABMA/ANSI/ISO/MIL

Precision ISO metric threads in Series KM, are manufactured to Class 4H. Precision bearing threads in Series MS-172236 are manufactured to MIL-S-8879. Precision bearing threads in Series MS-19068, N/AN, N-000, and NE are manufactured to National Standard Class 3.

Whittet-Higgins的螺母/垫圈

KML、KMM和KMS系列中的精密ISO公制螺纹按照4H级制造。NH、NL、NS和NT系列的精密轴承螺纹按照National Standard Class 3制造。NI系列的统一螺纹按照3B级制造。

Nuts/Washers of Whittet-Higgins Origin

Precision ISO metric threads in Series KML, KMM, and KMS are manufactured to Class 4H. Precision bearing threads in Series NH, NL, NS, and NT are manufactured to National Standard Class 3. Unified threads in Series NI are manufactured to Class 3B.

Collars

主要系列有BL、CCC、CC-A、CCS、CCM、SC、SC-A、SC-S

转接套/Adapter Sleeves

主要系列有SNW-00、SNW-100、SNW-3100

工具/Tools

主要系列有BAS、BASM、PAS、RTD、RTDM

硬舌垫圈

HTW系列介绍

内孔带键的硬化垫圈,其键限制键轴上的径向运动,其硬化可保护软锁紧垫圈。作为组件中的垫片和防止重旋转推力载荷非常有用。

Hardened Tongued Washers

HTW

Hardened washers with key at inner bore, the key of which limits the radial movement on a keyed shaft and the hardening of which protects soft lockwashers. Very useful as a spacer in assemblies and protection against heavy rotational thrust loads.

WHITTET-HIGGINS常用系列介绍及选型

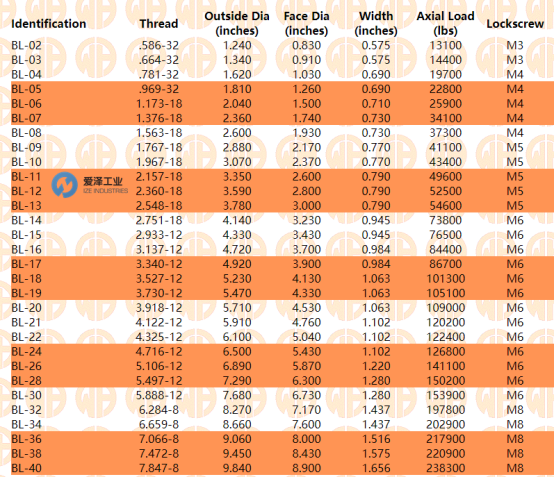

WHITTET-HIGGINS垫圈BL系列介绍及选型

BEARLOK 多功能机械锁紧螺母可调整、预加载并将轴承和其他部件固定到动力传动组件的轴和心轴上,具有最一致的精确度垂直度、中心线对齐以及从加载到锁定程序的轴向位置。其强大的均匀圆周锁定深入到轴或主轴螺纹中,可防止因振动、冲击和重载而松动。精度和一致性的这些优势使其成为无数机械和设备的理想螺纹固定装置。在与其他自锁装置的操作和比较测试中,BEARLOK 已经证明了其在精确对准和保持力方面的优势。

The BEARLOK versatile mechanical lock retaining nut adjusts, pre-loads, and secures bearings and other components to the shafts and spindles of power transmission assemblies with the most consistent precision squareness, centerline alignment, and the axial location from loading through locking procedures. Its strong uniform circumferential locking deep into the shaft or spindle threads prevents loosening from vibration, shock, and heavy loads. These benefits of precision and consistency make it the ideal threaded retaining device for an infinite array of machinery and equipment. In operational and comparative testing against other self-locking devices the BEARLOK has demonstrated its superiority in precision alignment and holding power.

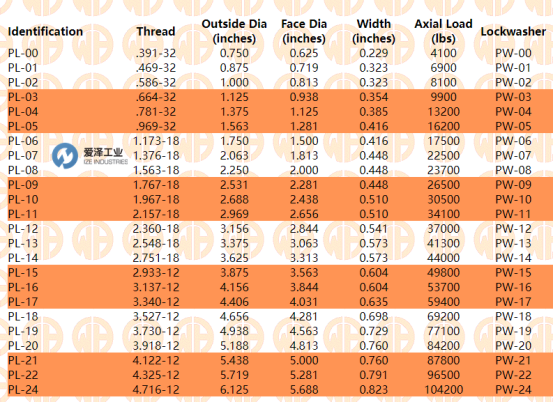

WHITTET-HIGGINS螺母PL系列介绍及选型

该系列精密左旋锁紧螺母结合了NL 系列左旋锁紧螺母的所有优点和精度优势,以确保轴承或动力传输组件的更长寿命,以及在以下情况下保持的额外安全性轴或主轴旋转得非常快。

轴承面与螺纹中径的跳动和平行度具有一圈总指示器读数不大于:00 到 06 尺寸为 0.0005 英寸,07 到 24 尺寸为 0.001 英寸。

This series of precision left-hand locknuts combines all the advantages of the NL series of left-hand locknuts with the benefits of precision to assure the longer life of a bearing or power transmission assembly, as well as the extra security of holding in situations where a shaft or spindle is revolving very rapidly.

The runout and parallelism of the bearing face to the pitch diameter of the threads have a one revolution total indicator reading no greater than: .0005 inches for sizes 00 through 06, .001 inches for sizes 07 through 24.

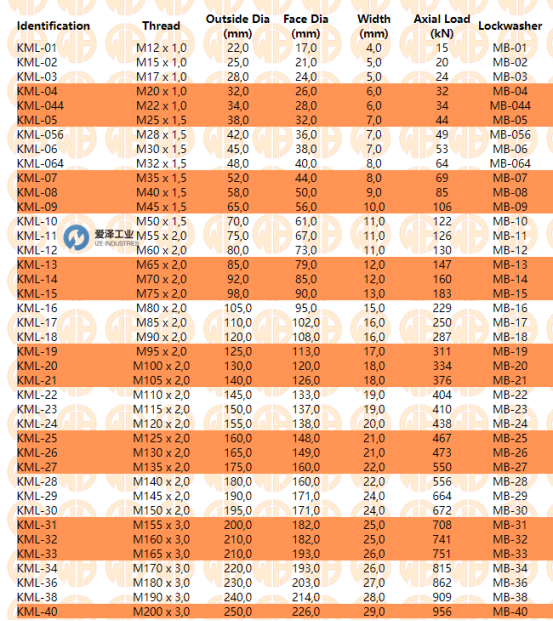

WHITTET-HIGGINS螺母KML系列介绍及选型

采用左旋螺纹设计,以确保更大的锁定力,螺纹以与大多数组件的轴旋转方向相反的方向缠绕 - 右手方向。这些螺母在赛车和设备驱动的高转速应用中变得重要。此外,它们在将右旋螺纹和左旋螺纹应用于轴的相对端的应用中表现得非常好,以便以更有效的方式轻松拧紧和松开动力传输组件。

Designed with a left hand thread to assure greater locking power the thread winds in the direction opposite that in which the shaft of most assemblies rotate - a right hand direction. These nuts have become important in applications of high rotational speeds of racing vehicles and equipment drives. Also they serve immeasurably well in applications where a right hand thread and a left hand thread are applied to opposing ends of a shaft to allow for an ease in tightening and loosening power transmission assemblies in a more efficient manner.

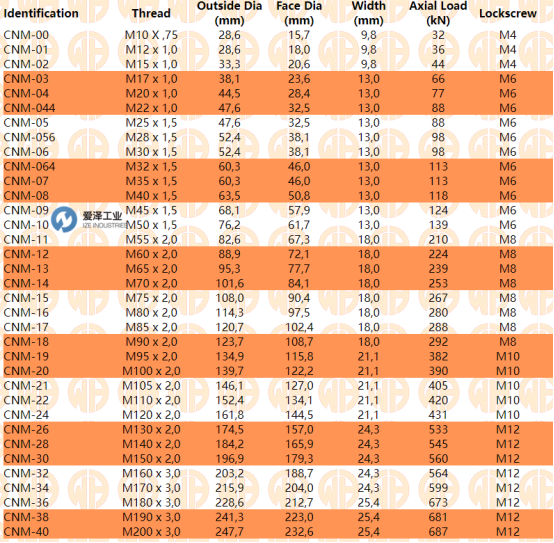

WHITTET-HIGGINS螺母CNM系列介绍及选型

该系列夹紧螺母具有符合ISO公制标准的轴承螺纹、配合和公差,因此可与越来越多地用于轴承和其他动力传输组件的公制保持装置完全互换。这些螺纹符合ISO 965标准。

轴承面—具有高于面直径的间隙释放的一侧 - 加工成与螺纹的中径轴线成直角,因此一转的跳动总指示器读数偏差不大于:50微米(0.002英寸)用于00至14尺寸,100微米(0.004英寸)用于15至40尺寸。

This series of CLAMP NUTS has the bearing threads specified to the ISO Metric standards, fits, and tolerances thus are fully interchangeable with metric retaining devices increasingly used in bearing and other power transmission assemblies. These threads are in accordance with the ISO Standard 965.

The bearing face - the side with the clearance relief above the face diameter - is machined square to the axis of the pitch diameter of the threads whereby the runout for one revolution has a total indicator reading variance no greater than: 50 Microns (.002 inches) for sizes 00 to 14, 100 Microns (.004 inches) for sizes 15 to 40.

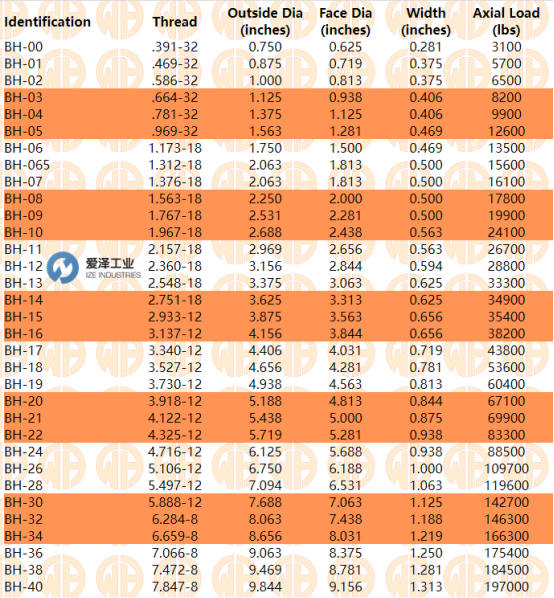

WHITTET-HIGGINS螺母BH系列介绍及选型

该系列BEARHUG锁紧螺母带有尼龙套环,是精密的自锁螺母。它设计用于与N和AN锁紧螺母相同的轴尺寸,但具有自锁和超精密的附加功能,其中它已成为精密轴承和动力传输组件的最重要部件。

这些螺母的轴承面与其螺纹中径之间的跳动具有一圈总指示器读数不大于:00到04尺寸为0.0004英寸,05至20尺寸为0.0006英寸,05到20尺寸为0.0008英寸21 到 40。

座位表面在40微英寸以内。

This series of BEARHUG Locknuts, with a nylon collar, is the mainstay of the precision self-locking nuts. It is designed for the same shaft dimensions as are the N and AN locknuts, but with the added features of self-locking and super precision wherein it has become a most important component for precision bearing and power transmission assemblies.

The runout of the bearing face of these nuts to the pitch diameter of their threads have a one revolution total indicator reading no greater than: .0004 inches for sizes 00 through 04, .0006 inches for sizes 05 through 20, .0008 inches for sizes 21 through 40.

Seating surface is within 40 micro-inches.

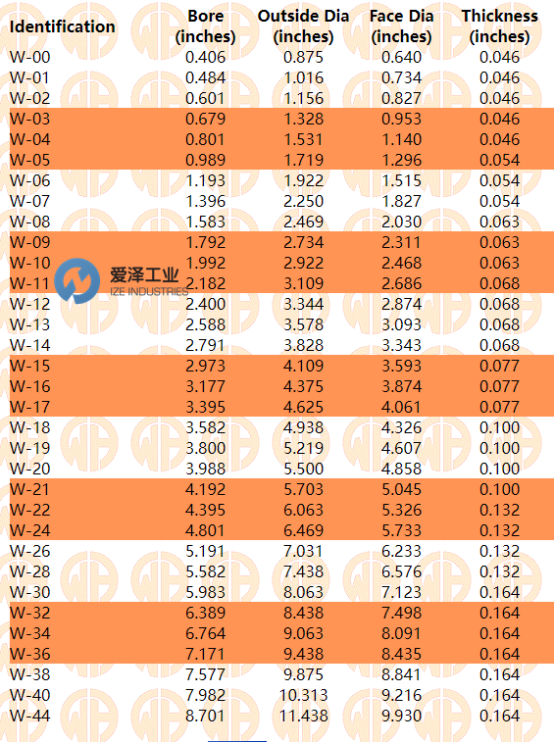

WHITTET-HIGGINS垫圈W系列介绍及选型

最常用的锁紧垫圈。它们由足够柔软的材料制成,因此柄脚可以承受组装中的多次锁定和解锁弯曲,但材料足够坚硬以抵抗可能由扳手槽角施加的剪切作用。键沿与柄脚相反的方向弯曲并沿轴轴向弯曲,以安装在轴承座圈下方的轴键槽中,从而为剪切作用提供更大的阻力,并为轴承的内座圈提供支撑。

Most commonly used lockwashers. They are made of a material sufficiently soft so the tangs will withstand several bends of locking and unlocking in assembly, but of a material sufficiently hard to resist the shearing action which may be exerted by the corner of the spanner slots. The key is bent in the opposite direction of the tang and axially to the shaft to fit in a shaft keyway under the bearing race to provide greater resistance to the shearing action and to provide support with the inner race of the bearing.

如果您需要完整的WHITTET-HIGGINS相关技术咨询,请随时致电爱泽工业(021-3100 6702),或者访问网站www.ize-industries.com,我们将尽全力解决您的问题。

If you have any question for WHITTET-HIGGINS,please feel free to dial 0086-21-3100 6702 or browse our website: www.ize-industries.com.

IZE-industries

Contact Information:

Tel:0086-21-31006702 or 0086-21-35350722

Fax:0086-21-35350711

Mobile:0086-189 1750 1433

E-mail:sales@ize-industries.com

Website:www.ize-industries.com

沪公网安备31011002006738号

沪公网安备31011002006738号