了解液压球阀系统的功能(中英文)

在当今瞬息万变的工业技术领域,液压球阀已成为流体控制系统中不可或缺的组成部分。它在众多不同工艺流程中发挥着关键作用,确保系统平稳可靠地运行。随着各行业不断追求更高的性能和效率,高质量液压解决方案的重要性不言而喻。

In today’s fast-changing world of industrial tech, the Hydraulic Ball Valve has really become an essential part of fluid control systems. It plays a key role in keeping things running smoothly and reliably across a bunch of different processes. As industries aim for better performance and efficiency, the importance of high-quality hydraulic solutions can’t really be overstated.

液压球阀系统及其应用概述

Overview of Hydraulic Ball Valve Systems and Their Applications

液压球阀系统在许多工业应用中都至关重要——它们能够精准控制流体流量。这些阀门内部有一个球形部件,根据其位置(完全打开或完全关闭)来控制管道的开启或关闭。它们通常用于液压系统,其优点在于压力损失极小且能够处理高流量。因此,它们成为制造业、石油天然气行业以及水处理厂等行业的首选。

在考虑安装液压球阀时,务必确保其与系统兼容。注意阀门的材质——如果处理的是腐蚀性流体,不锈钢等材质是理想之选。另一方面,在腐蚀性较小的环境中,黄铜材质可能就足够了。

温馨提示:定期维护对于延长阀门的使用寿命和保持最佳性能至关重要。定期检查泄漏情况,并保持所有部件润滑良好——这些小细节可以预防代价高昂的故障,并有助于延长阀门部件的使用寿命。

此外,不要忽视执行器部件——它控制着阀门运行的速度和可靠性。可以选择电动或气动执行器,但具体选择应取决于需求:快速响应、精确控制,或者两者兼顾。

另一个小技巧:选择能够提供状态反馈的执行器。这样,可以更轻松地监控所有部件的运行状况,并平稳地管理系统。

Hydraulic ball valve systems are pretty key in a bunch of industrial setups—they’re great at giving you precise control over fluid flow. Basically, these valves have a spherical piece inside that opens or blocks the pipe depending on their position—either fully open or completely closed. You’ll usually see them in hydraulic systems, and they’re awesome because they cause very little pressure loss and can handle high flow rates. That’s why they’re a go-to choice in industries like manufacturing, oil and gas, or water treatment plants.

When you're thinking about installing hydraulic ball valves, it’s really important to make sure they’ll work well with your system. Pay attention to the material—stuff like stainless steel is perfect if you’re dealing with corrosive fluids. On the other hand, brass might do just fine in less aggressive environments.

Quick tip:Regular upkeep is super important if you want these valves to last and perform at their best. checking for leaks now and then, keeping everything well-lubricated—these little things can prevent costly breakdowns and help extend how long your valve components stay in good shape.

Also, don’t overlook the actuator part—it’s what controls how fast and reliably the valve operates. You can go with electric or pneumatic actuators, but your choice should depend on what you need: fast responses, precise control, or maybe a mix of both.

Another quick tip: choose actuators that give you feedback on their status. That way, it’s easier to keep an eye on everything and manage your system smoothly.

液压球阀的关键部件和设计注意事项

Key Components and Design Considerations for Hydraulic Ball Valves

液压球阀在流体控制系统中几乎是必不可少的——无论应用于何种领域,它们都可靠且易于维护。这些阀门主要由一个中间带孔的圆形球体构成,方便控制流体的通断。其主要部件包括阀体、球体、阀座、阀杆和执行机构。但实际上,这些部件的质量至关重要,因为任何一个部件出现故障都可能导致系统运行异常,甚至引发安全问题。

Hydraulic ball valves are pretty much essential in fluid control systems—they're reliable and easy to maintain, no matter what kind of application you're dealing with. Basically, these valves are made with a round ball that has a hole right through the middle, making it simple to turn the flow on or off. The main parts you'll find are the body, the ball itself, seats, the stem, and the actuator. But honestly, the quality of these parts really matters, because if any of them fail, it can cause system hiccups or even safety issues.

在进行设计时,压力等级、所用材料以及阀门密封性能等因素至关重要。选用不锈钢或碳钢等坚固耐用的材料优势显著,因为它们能够承受严苛的工况并具有良好的耐腐蚀性。此外,良好的密封性能也至关重要——采用合适的密封解决方案,阀门的使用寿命可延长40%以上。

When you're thinking about design, things like pressure ratings, the materials used, and how well the valve seals are super important. Going for sturdy materials like stainless steel or carbon steel really pays off because they stand up to tough conditions and resist corrosion. Plus, having good seals can make a big difference—you might see operation lifespans extend by over 40% with the right sealing solutions.

工作原理:液压球阀如何控制流体流动

Operating Principles: How Hydraulic Ball Valves Control Fluid Flow

液压球阀在各种系统中控制流体方面至关重要。它们的工作原理其实非常简单:一个中间带孔的球体在阀体内部旋转。转动手柄时,球体旋转——如果孔与管道对齐,流体即可顺畅通过;旋转90度,通道被密封,流体停止流动。虽然结构简单,但其控制速度快、可靠性高,因此深受工业界的青睐。

更妙的是,它们的设计有助于保持流体流动平稳——减少湍流和压降。由于球体是球形的,流体流动顺畅,能量损失也更小。此外,这些阀门可以手动操作,也可以设置为自动控制,根据需求提供多种选择。它们还非常坚固耐用,耐磨损,因此非常适合重载环境。所有这些优点加起来,造就了一个可靠的部件,能够确保液压系统高效、安全地运行,而且无需太多麻烦。

Hydraulic ball valves are pretty crucial when it comes to controlling fluids in various systems. They’re actually pretty straightforward in how they work: there’s a ball with a hole in the middle that spins inside a housing. When you turn the handle, the ball rotates—if the hole lines up with the pipe, fluids flow right through; turn it 90 degrees, and the passage gets sealed off, stopping the flow. It’s a simple setup, but it does the job really quickly and reliably, which is why folks in industry love using them.

What’s pretty neat is that their design helps keep things smooth—less turbulence and fewer pressure drops. Because the ball is spherical, the fluid moves easily, and there’s less energy lost in the process. Plus, these valves can be operated manually or set up for automatic control, giving you lots of options depending on what you need. They’re also built tough—resisting wear and tear—so they’re perfect for heavy-duty environments. All that adds up to a reliable part that keeps hydraulic systems running efficiently and safely, without a lot of hassle.

了解液压球阀系统的功能

Understanding the Functionality of Hydraulic Ball Valve Systems

性能指标:阀门的压力等级和流量系数

Performance Metrics: Pressure Ratings and Flow Coefficients in Valves

液压球阀在各种工业装置中控制流体流量方面至关重要。众所周知,它们的性能主要取决于一些可测量的因素,例如压力等级和流量系数。根据《2022 年液压阀市场报告》中的内容,合适的压力等级对于确保系统平稳运行至关重要——大多数优质液压球阀的额定压力在 1500 psi 到 3000 psi 之间。这样,它们就能轻松应对较高的压力。

此外,还有流量系数(Cv)——它基本上反映了阀门的流体通过效率。美国国家标准协会 (ANSI) 指出,更高的 Cv 值意味着阀门可以允许更多的流体通过,这对于需要高效流量的系统来说非常有用。从《2023年阀门技术概览》中我了解到,大多数液压球阀的流量系数(Cv)在10到400之间。尺寸较大的球阀通常具有更高的流量系数,这意味着它们可以处理更大的流量,甚至有助于系统节能。

对于工程师而言,了解这些参数——压力等级和流量系数——至关重要,因为这有助于他们选择合适的阀门,并设计出高效可靠的液压回路。

Hydraulic ball valves are really key when it comes to controlling fluid flow in all sorts of industrial setups. You know, their performance really depends on some mainly measured factors like pressure ratings and flow coefficients. According to what I saw in the 'Hydraulic Valves Market Report 2022', having the right pressure rating is super important to keep everything running smoothly—most of the high-quality hydraulic ball valves are rated between about 1500 psi to 3000 psi. That way, they can handle pretty high pressures without a hitch.

And then there's the flow coefficient, or Cv—this is basically how well a valve can pass fluid through it. The ANSI (American National Standards Institute) says that a higher Cv means the valve can let more fluid through, which is pretty handy when you're dealing with systems that need efficient flow. From the 'Valve Technology Overview 2023', I learned that most hydraulic ball valves have Cv ratings anywhere from about 10 to 400. Larger ones usually have higher Cv ratings, which means they can handle bigger flow rates and even help save energy in the system.

For engineers, understanding these things—pressure ratings and Cv—is actually pretty important because it helps them pick the right valves and design hydraulic circuits that work efficiently and reliably.

液压阀最佳功能安装最佳实践

Installation Best Practices for Optimal Functionality of Hydraulic Valves

安装液压阀系统时,遵循行之有效的最佳实践至关重要,它能确保系统运行顺畅,使用寿命更长。一切都始于正确的开始——因此,在开始安装之前,请仔细检查系统需求,例如流量和压力水平。确保阀门与管道完美对齐,可以避免不必要的麻烦,甚至防止日后造成高昂的损失。此外,切勿忽视正确密封的重要性——使用合适的材料和技术可以有效防止泄漏,否则泄漏会消耗能源并增加运营成本。

When you're installing hydraulic valve systems, sticking to tried-and-true best practices really makes all the difference in getting things to work smoothly and last longer. It’s all about starting off on the right foot—so, take a close look at what the system needs, like flow rates and pressure levels, before you begin. Making sure the valve lines up perfectly with the pipes can save you from unnecessary stress and even some costly damage down the line. And don’t forget the importance of sealing things up right—using the right materials and techniques can go a long way in preventing leaks, which otherwise eat up energy and hike up operational costs.

如果对尖端技术更感兴趣,可以考虑使用能量利用系数等选项来提升系统效率。例如,选择泵-涡轮(PaT)配置并确定其最佳工作点,可以有效提高能量捕获率,尤其是在供水管网中。这不仅能提高系统效率,还能与液压阀协同工作,有效控制压力波动,从而延长两个系统的使用寿命。此外,定期维护和密切关注也至关重要。及早发现问题可以避免日后诸多麻烦,并确保系统始终处于最佳运行状态。

总而言之,精心规划和持续维护才能够确保液压阀系统长期可靠高效地运行。

Now, if you’re into cutting-edge tech, there are options like energy exploitation coefficients that can actually boost your system’s efficiency. For example, choosing a pump-as-turbine (PaT) setup and figuring out its best working point can really help with capturing energy, especially in water distribution networks. Not only does this make your setup more efficient, but it also plays nice with hydraulic valves by keeping pressure fluctuations in check, which helps both systems last longer. Oh—and don’t forget, regular maintenance and keeping an eye on things is super important too. Spotting issues early can save a lot of headaches later on and keeps everything running at its best.

All in all, a bit of careful planning and ongoing care can make your hydraulic valve system run more reliably and efficiently for the long haul.

液压阀技术的未来趋势及行业创新

Future Trends in Hydraulic Valve Technology and Industry Innovations

展望未来,液压阀技术的发展前景令人振奋,一些极具潜力的趋势正在席卷整个行业。其中一个显著的趋势是向更智能的系统转型,这些系统将物联网 (IoT) 技术融入其中。 MarketsandMarkets 的一份报告指出,全球智能阀市场预计将从 2021 年的约 27 亿美元跃升至 2026 年的约 64 亿美元——复合年增长率高达近 19.3%!主要驱动因素是什么?各行各业越来越渴望自动化和预测性维护,以确保设备平稳运行,尤其是在石油天然气、水资源管理和制造业等领域。

此外,如今对可持续发展的追求日益高涨,这催生了许多创新,催生了新材料和新设计。越来越多的可生物降解润滑剂和轻质复合材料被应用于液压系统中。这些变革不仅有助于企业遵守严格的环境法规,还能提升业绩。据市场研究公司Research and Markets最近的一项研究显示,环保型液压系统市场预计到2025年将以每年约11%的速度增长。所有这些创新都至关重要,因为各行各业都需要在满足严格的环境标准的同时,确保效率和效益不受影响。

Looking ahead, the future of hydraulic valve technology is pretty exciting, with some pretty cool trends on the horizon that are really shaking things up in the industry. One big thing that's standing out is the move towards smarter systems that tap into IoT (Internet of Things) tech. I came across a report from MarketsandMarkets saying that the global market for smart valves is expected to jump from about $2.7 billion back in 2021 to around $6.4 billion by 2026 — that's a hefty CAGR of nearly 19.3%! The main drivers? Well, industries are increasingly craving automation and predictive maintenance to keep things running smoothly, especially in fields like oil and gas, water management, and manufacturing.

On top of that, there's a big push for sustainability these days, which is sparking some really innovative stuff with new materials and designs. We're seeing more biodegradable lubricants and lightweight composites making their way into hydraulic systems. Not only do these changes help companies stay compliant with tough environmental rules, but they also boost performance. According to a recent study from Research and Markets, the eco-friendly hydraulic systems market is expected to grow at about 11% annually through 2025. All these innovations are super important because industries need to meet strict environmental standards without sacrificing efficiency or effectiveness.

液压阀技术的未来发展趋势

Future Trends in Hydraulic Valve Technology

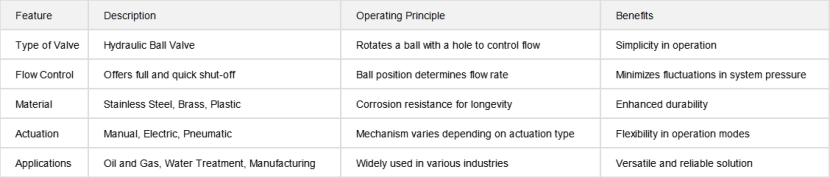

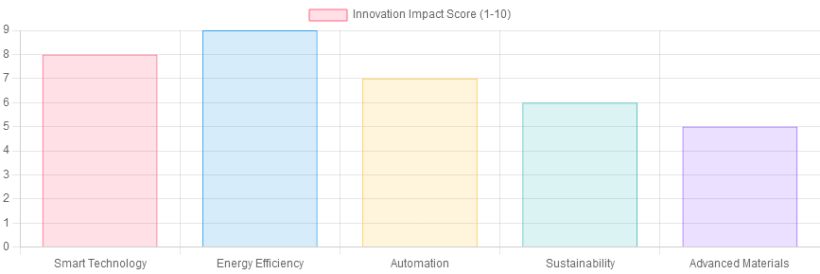

该图表展示了未来液压阀技术创新预计带来的影响,重点关注智能技术、能源效率、自动化、可持续性和先进材料等关键领域。每个领域均根据其在行业中的预期重要性,按 1 到 10 的等级进行评分。

This chart illustrates the projected impact of future innovations in hydraulic valve technology, focusing on key areas such as smart technology, energy efficiency, automation, sustainability, and advanced materials. Each area is rated on a scale from 1 to 10 based on anticipated significance in the industry.

结论

Conclusion

液压球阀在众多工业应用中控制流体流量方面至关重要。如果想了解其工作原理,不妨了解一下主要部件,例如阀体、球体和阀座,并思考使其性能优异的设计选择。简而言之,这些阀门通过旋转球体来控制流体的流动,从而实现开启或关闭,其巧妙之处在于能够高效应对各种压力状况。选择阀门时,务必关注压力等级和流量系数等参数,以确保系统运行平稳可靠。

Hydraulic ball valves are pretty essential when it comes to managing fluid flow in a bunch of different industrial setups. If you’re curious about how they actually work, it’s helpful to look at the main parts—like the valve body, the ball itself, and the seats—and also consider the design choices that make them perform well. Basically, these valves do their thing by turning the ball to open or close the flow of fluid, which is pretty neat because they handle different pressure situations really effectively. When you're choosing a valve, paying attention to things like pressure ratings and flow coefficients is super important to make sure everything runs smoothly and reliably.

声明:

-文章转载自3E Industry,由爱泽工业翻译,如有侵权,请联系删除!

-如有偏颇,欢迎指正!

沪公网安备31011002006738号

沪公网安备31011002006738号