LVDT、半桥和数字变换理论

感应技术

Inductive Technology

工作原理

LVDT 位移传感器通过将核心移动穿过主体来工作。铁芯在体内的位置由绕在骨架上的线圈检测。向线圈提供交流信号,然后返回交流信号。然后通过调节电子设备处理该信号,以提供核心位置的测量值。主体通常安装在元件的静态部分上,而核心连接在运动部分上。图中显示了简化的电气原理图。

Principle of Operation

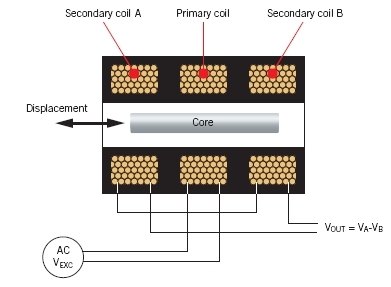

A LVDT Displacement Sensor works by moving the core through the body. The position of the core within the body is detected by coils wound on the bobbin. The coils are supplied with an AC signal and then returned an AC signal. The signal is then processed by conditioning electronics to provide a measure of the core position. The body is normally mounted on the static part of an element and the core attached to the moving part. A simplified electrical schematic is shown in the figure.

次级线圈 A 和 B 反向串联,使两个电压 VA 和 VB 相位相反,换能器输出为 VA-VB。如果铁芯位于中心位置,则每个次级将感应出大小相等但相位相反的电压,净输出为零。当铁芯沿一个方向移动时,相应次级线圈中的电压会增加,而另一个线圈会经历互补的电压降低。净效应是与位移成正比的传感器电压输出。了解输出相对于激励信号的幅度和相位允许人们从零位推导出芯运动的位置和方向。

The secondary coils A and B are connected in series opposition so that the two voltages VA and VB have opposite phase and the transducer output is VA-VB. If the core is in the centre position then voltages of equal magnitude but opposite phase will be induced in each secondary and the net output is zero. As the core is moved in one direction, the voltage in the corresponding secondary coil increases while the other coil experiences a complementary voltage reduction. The net effect is a transducer voltage output that is proportional to displacement. Knowledge of the magnitude and the phase of the output with respect to the excitation signal allows one to deduce the position and direction of the core motion from the null position.

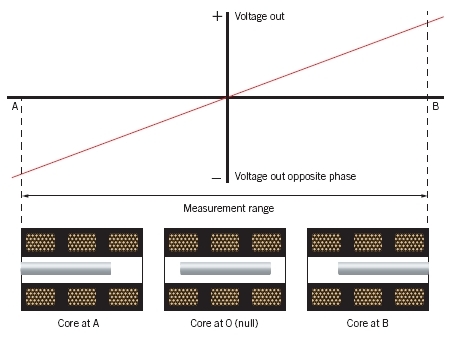

LVDT 的输出是其校准测量范围内位移的线性函数。超出这个范围,输出变得越来越非线性。测量范围定义为距传感器零位的 ± 距离。

The output of an LVDT is a linear function of displacement over its calibrated measurement range. Beyond this range the output becomes increasingly non-linear. Measurement range is defined as ± distance from the transducer null position.

半桥、LVDT 和数字传感器

Half Bridge, LVDT and digital transducers

线性可变差动变压器 (LVDT) 和半桥是线圈格式的两种替代方法,将在本节中进行介绍。LVDT 和半桥传感器将磁芯在通电线圈产生的磁场中的运动转换为可检测的电信号。

The linear Variable Differential Transformer (LVDT) and Half-Bridge are two alternative approaches to the coil format and are described in this section. LVDT and Half-Bridge transducers convert the movement of a core within the magnetic field produced by an energised coil into a detectable electrical signal.

传统半桥

Conventional Half Bridge

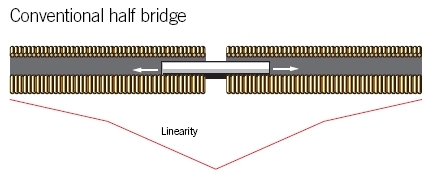

半桥传感器构成惠斯通电桥电路的一半,可以轻松确定从零开始的变化。电桥的另一半内置于放大器中。当磁芯处于中心位置时,两个信号 VA 和 VB 相等。随着铁芯移位,两个绕组的相对电感发生变化,从而产生 VA 和 VB 的互补变化。

The Half Bridge transducer forms half of a Wheatstone bridge circuit, which enables change from null to be readily determined. The other half of the bridge is built into the amplifier. When the core is in a central position, the two signals VA and VB are equal. As the core is displaced, the relative inductance of the two windings changes producing a complimentary change in VA and VB.

传统的 LVDT

Conventional LVDT

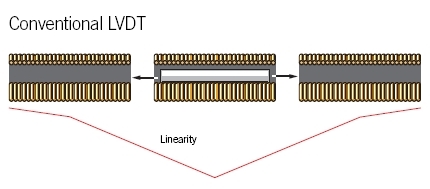

当磁芯处于中心位置时,从初级 (VEXC) 到每个次级的耦合相等,因此 VA=VB 且输出 Vout=0。随着磁芯的位移,VA 与 VB 不同,输出 VOUT 的幅度和相位与运动成比例变化。

When the core is in a central position, the coupling from the primary (VEXC) to each secondary is equal, so VA=VB and the output Vout=0. As the core is displaced VA differs from VB, and the output VOUT changes in magnitude and phase in proportion to the movement.

Solartron LVDT

Solartron LVDT

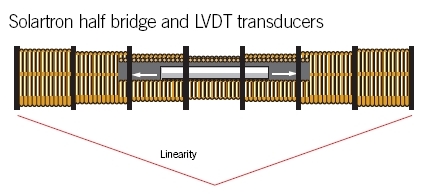

Solartron Metrology 不断开发精密线轴模具和多腔线圈绕组,确保在整个范围内具有出色的线性度和热稳定性。

Solartron Metrology's continuous development of precision bobbin mouldings and multi-chambered coil windings ensure excellent linearity and thermal stability throughout the range.

Solartron Orbit® 3 数字传感器

Solartron Orbit® 3 digital sensors

Solartron 计量数字传感器使用可溯源干涉仪进行校准,并颁发校准证书。所有数字传感器都配有集成电子设备,可存储探头 ID、范围、校准误差等信息。与传统模拟传感器相比,数字传感器具有卓越的性能。本目录中引用的性能数据包括探头内的所有机械错误以及电子接口模块中的任何错误。

Solartron Metrology Digital Sensors are calibrated using a traceable interferometer and are issued with a calibration certificate. All digital transducers are fitted with integrated electronics, which store information such as probe ID, range, calibration error, etc. Digital sensors provide superior performance compared to traditional analogue sensors. Performance figures quoted in this catalogue include all mechanical errors within the probe head together with any errors in the electronics interface modules.

本文翻译自AMETEK SOLARTRON

沪公网安备31011002006738号

沪公网安备31011002006738号