什么是SIL认证(液位开关示例)丨您的等级申请是否需要它?

什么是 SIL 认证,它有什么作用?

What is a SIL Certification and What Does It Do?

安装经过 SIL 认证的液位传感器时,该安装已通过安全和过程认证。这些在各种标准中定义,例如 IEC 61508,涵盖电气、电子和可编程安全相关系统的功能安全。

When installing a SIL certified level sensor, the installation is certified regarding safety and process. These are defined in various standards, such as IEC 61508, that cover functional safety of electrical, electronic and programmable safety related systems.

SIL 系统简化:

SIL1 – 保证产品始终测量的较低级别

SIL2 – 产品中您不知道的低故障统计风险

SIL3 – 冗余测量能力 – SIL2 和 SIL3 之间的主要区别之一

SIL4 – 市场上可用的仪器非常少,为此获得认证的要求极为苛刻。用于例如铁路电子设备。

The SIL system simplified:

SIL1 – Lower level guarantee that the product will measure all the time

SIL2 – Low statistical risk of failure that you do not know about in the product

SIL3 – Redundant measurement capability – one of the primary differentiators between SIL2 and SIL3

SIL4 – Very few instruments available on the market, and extremely harsh demands to be certified for this. Used e.g. for railways electronics.

制造商基本上可以通过满足 SIL2 标准和相关 IEC 61508 标准来证明自己,但由外部公司或顾问进行计算时,对风险和性能的真实和客观评估更为可靠。在这种情况下,方式称为 FMEDA……

Manufacturers can basically certify themselves by fulfilling the standards of SIL2 and the relevant IEC 61508 standards, but a true and objective evaluation of risk and performance is more reliable when performed by an external company or consultant doing the math. In this case the math is called FMEDA…

什么是 FMEDA?

What is FMEDA?

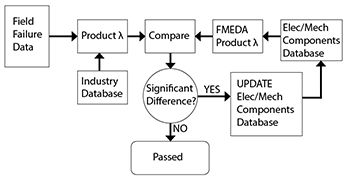

故障模式、影响和诊断分析是一种全面的分析,将每个单独的组件都考虑在内。该分析将单个组件的统计数据与安装基础的所有已知故障、由于产品设计、制造和操作程序(如持续维护)引起的故障进行比较。

Failure Modes, Effects and Diagnostics Analysis is a thorough analysis that takes every individual component in consideration. The analysis compares the statistics from the individual component with all known failures from the installment base, failures due to product design, manufacturing and operating procedures such as ongoing maintenance.

通过使用外部顾问进行此分析,制造商可以获得宝贵的工业统计数据和有关产品的许多关键问题。这可能会使制造商更难获得认证,但与此同时,获取统计数据和行业知识只会使认证更有价值。

By using external consultants for this analysis, the manufacturer achieves access to invaluable industrial statistics and numerous critical questions regarding the product. This might make the certification harder to achieve for the manufacturer, but at the same time, access to statistics and industrial knowledge only makes the certification more valuable.

经 SIL2 认证的液位传感器的价值

The Value of a SIL2 Certified Level Sensor

市场上有各种各样的液位传感器。其中一些液位传感器根本没有经过认证,有些经过了 SIL1 认证,有些经过了 SIL2 认证。通常,经过 SIL2 认证的液位传感器的价格高于经过 SIL1 认证或非认证版本的价格,那么什么时候需要花额外的钱来选择 SIL1 甚至 SIL2 认证的液位传感器呢?

A wide variety of level sensors are available on the market. Some of these level sensors are not certified at all, some are SIL1 certified and some of them are SIL2 certified. Typically, the price of a SIL2 certified level sensor is higher than the price of the SIL1 certified or non-certified versions, so when is it relevant to spend the extra money and choose a SIL1, or even a SIL2 certified level sensor?

问问自己这些问题:如果浮顶储罐、化学品储罐或暴风雨施工储罐发生溢出,可以计算哪些费用?花费多少工作时间来检查工作的设备?您是否因液位开关故障而发生故障,成本是多少?为了降低风险、提高安全性并同时减少监控和验证液位传感器是否正常工作的时间,SIL 认证的液位传感器物有所值。简而言之,经过 SIL 认证的液位传感器可能比未经过 SIL 认证的液位传感器贵一些,但多出来的钱是在其他领域赚到的。

Ask yourself these questions: What expenses can be calculated if a floating roof tank, a chemical tank or a stormflow construction tank experiences overflow? What number of working hours are spent on checking equipment that works? Have you experienced breakdowns due to level switch failure, and what were the costs? To lower the risk, increase safety and at the same time decrease hours spent on monitoring and verifying that the level sensors work correctly, a SIL certified level sensor is worth the value. In short, a SIL certified level sensor might be a bit pricier than a level sensor that is not SIL certified, but the extra money spent are earned in other areas.

对于许多过程工业应用,工程师熟悉危险区域的认证。这些是众所周知的要求,可确保电气设备在潜在爆炸性环境中的安全运行。为了确保仪器的可靠性并正常运行,经过 SIL 认证的液位传感器是确保工作流程自动化的重要步骤。此外,使用经过 SIL2 认证的液位传感器可确保每个单独组件的质量,并根据已安装仪器的经验来保持这一点。

For many process industry applications Engineers are familiar with hazardous area approvals. These are well known requirements ensuring the safe operation of electrical equipment in potentially explosive environments. For reliability and to ensure proper operation of your instrumentation, a SIL certified level sensor is an important step in securing the automation of the workflow. Furthermore, using a SIL2 certified level sensor ensures the quality of every individual component and holds this up against experience from an installed base of instruments.

不仅仅是技术知识

More than Technical Knowledge

除了彻底的技术分析外,SIL2 认证还需要自动产品验证。这意味着液位开关能够自动运行测试,以电子方式验证测量仪器是否按预期工作。如果测试结果为异常,自动验证功能将自动提醒工作人员。此功能对远程应用程序或由于位置而不易监控的应用程序特别有用。此功能可以称为浪费保护——它可以防止浪费工作时间来检查有效的设备,并使工作人员能够更有效地专注于工作日。

Besides the thorough technical analysis, a SIL2 certification also demands an automatic product verification. This means that a level switch is capable of automatically running tests to electronically verify that the measuring instrument works as intended. If the test comes out with a negative result the auto-verify functionality will automatically alert the staff. This feature is especially beneficial on remote applications, or applications that are not easily monitored due to location. This functionality could be named a waste-protection – it protects from wasting working hours on checking equipment that works and allows the personnel a more efficient focus on a working day.

沪公网安备31011002006738号

沪公网安备31011002006738号